Input

- Pulper rags

Depending on the requirements, ANDRITZ plants include several shredding stages in order to break down the stubborn rags properly. The robust machine technology with its very hard wearing cutting gear releases the metals (accounting for up to 40% of the content) completely. Impurities are separated into different fractions by subsequent separation processes. The calorific materials are further processed to provide substitute fuels.

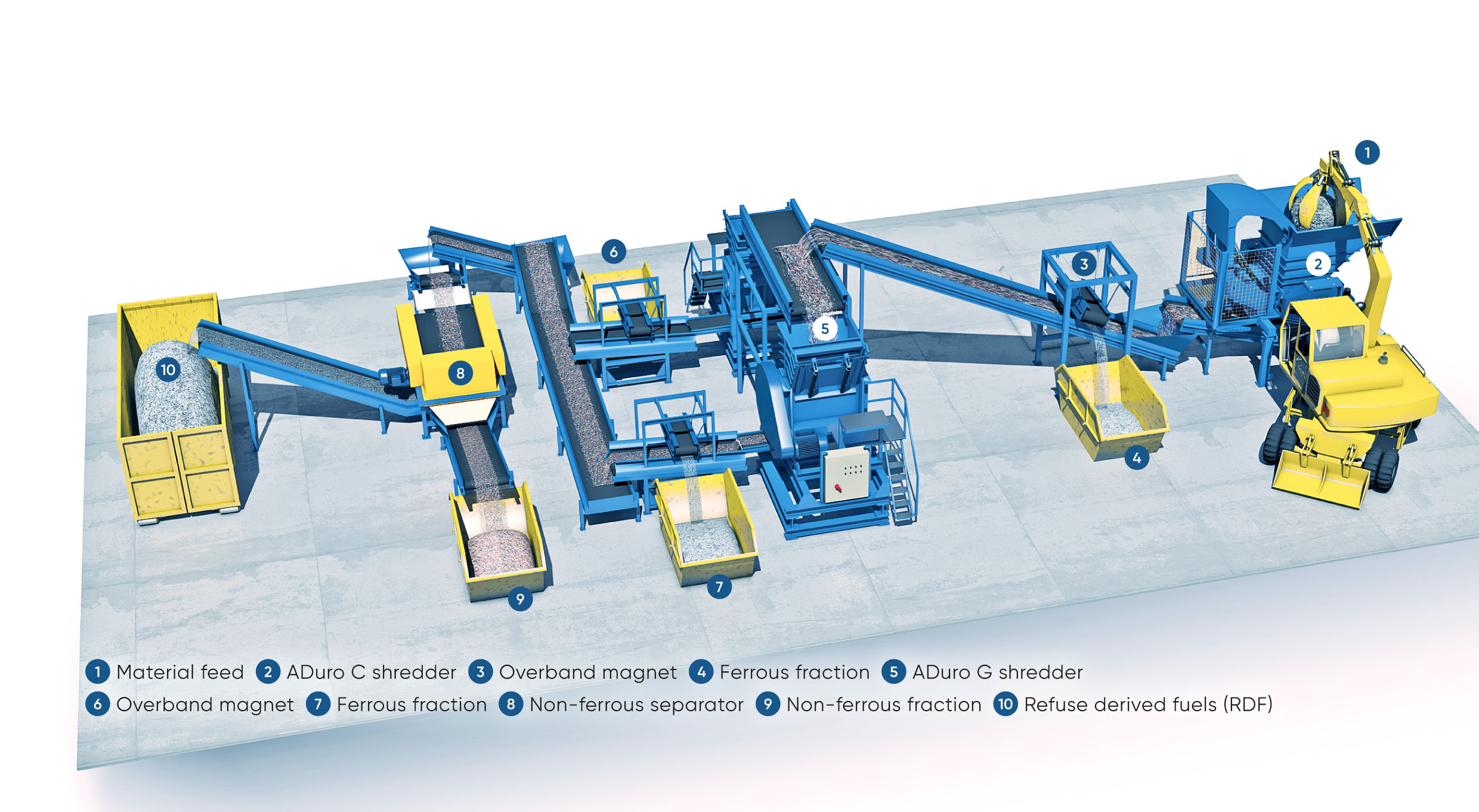

Pulper rags recycling plant

For tasks as demanding as the treatment of pulper rags, a two-stage process is recommended. The ADuro C shredder allows very flexible operation for rags of all lengths and diameters at high throughput rates of up to 15 t/h.

In order to avoid any quality issues in the substitute fuel fraction and other subsequent separation technologies, manual sorting can be applied after the first stage in order to remove contaminants from the process.

For reliable post-shredding of the pre-shredded pulper rags, the ADuro G shredder is the best choice. The material is grabbed by the fast-running rotor and shredded in interaction with the fixed stator knives.

For efficient removal of metal wires, it is important to cut the pre-shredded rags to a size of below 40 mm and to loosen up the material. This task is performed perfectly by the ADuro G.