Chemicals

- Phosphoric acid

Large filter sizes, with filter areas in excess of 200 square meters, eliminate the need for multiple smaller filters. The filter offers the facility to discharge the solids as a wet cake or dry cake, and provides exceptional wash efficiencies, in addition to maximum process control. In addition to phosphoric applications, the tilting pan filter has been used in metallurgical applications, such as copper ore, and in specialized applications, such as activated carbon.

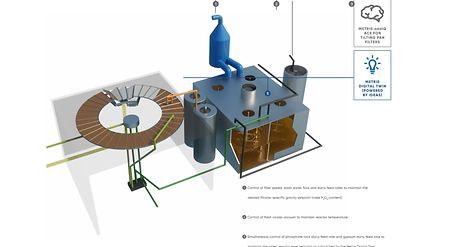

ANDRITZ tilting pan filter

Metris addIQ ACE for tilting pan filters (ACE = Advanced Control Expert) is a control optimization system that uses a series of Metris BrainWave MPCs (Model Predictive Controller) to determine the best setpoints. It manages the key process control loops, keeping costs as low as possible while continuously delivering a product that meets your specifications.

Furthermore, it manages all operating constraints and limits and sends operational targets to the plant’s automation system (DCS). Metris addIQ ACE continuously advises the operator on what is happening and why, also giving the operator an insight into how it analyzes and guides the process. With this customized solution, production is maximized while simultaneously minimizing the loss of phosphoric acid to tailings. It optimizes operation of the ANDRITZ tilting pan filter to maximize the concentration of the phosphoric acid product while minimizing loss of phosphoric acid in the gypsum by-product.

It also optimizes reactor operation by controlling temperature and level, as well as dynamically controlling residual sulphates during the reaction. The Metris Digital Twin of the process provides real-time feedback on key reactor values that would otherwise come from periodic lab samples. This allows Metris addIQ ACE to make continuous adjustments and tighten reactor control. The Metris addIQ ACE modules include control of reactor temperature and level, residual sulphate, reactor solids and density of filter tailings wash filtrate.

Benefits of Metris addIQ ACE for tilting pan filter: