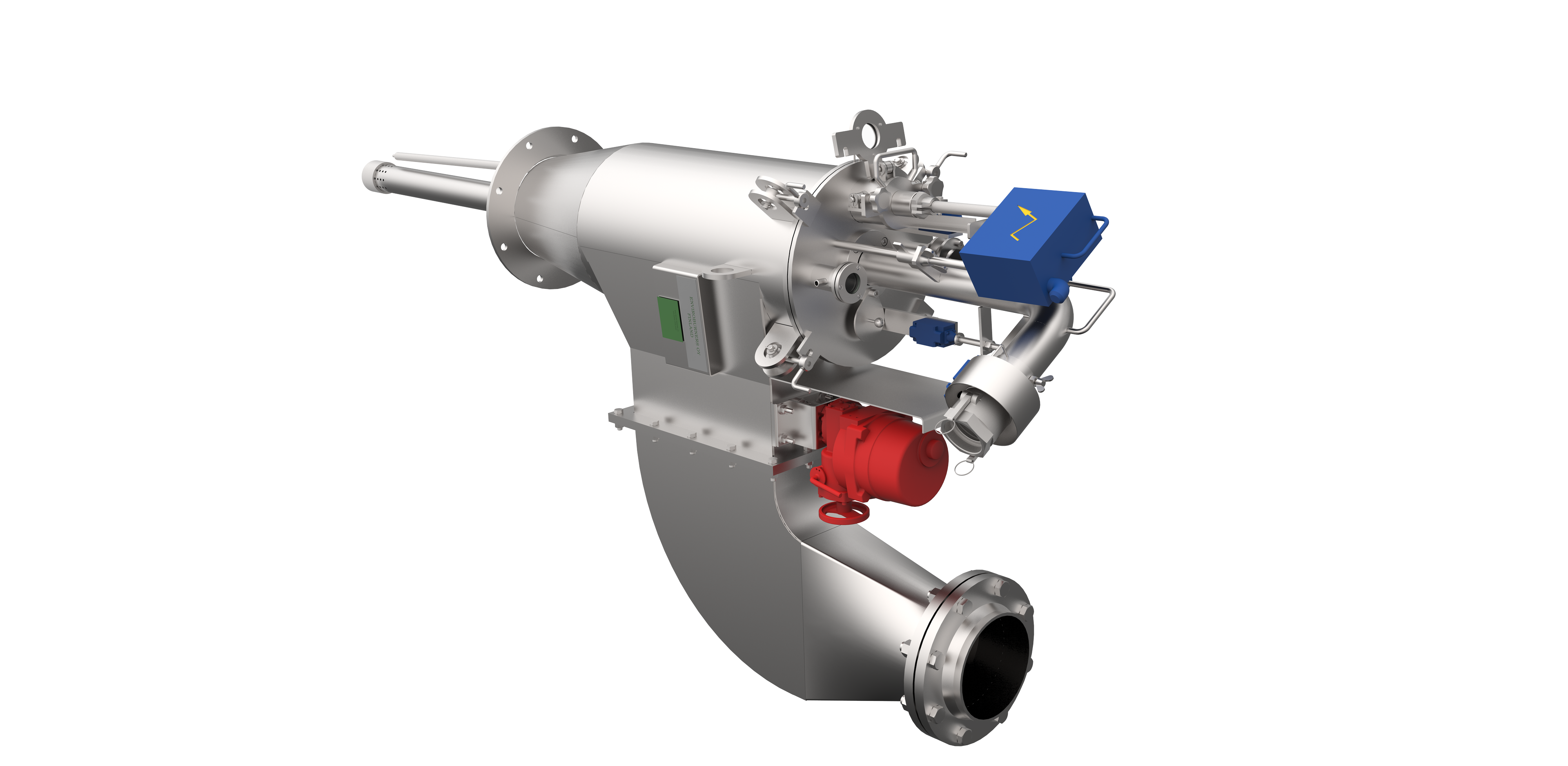

ANDRITZ burner solutions are designed to utilize industrial side streams, biofuels and other sustainable fuels to generate green energy thus reducing the CO2 footprint of the main process. Even streams previously considered as waste can be processed to produce valuable chemicals and raw materials instead of simply iicinerating them.

A good example is the pulp mill CNCG (Concentrated Non-Condensible Gas) collection system combined with a sulfuric acid production unit (SulfoLoop™). In the process the reduced sulfur rich CNCG stream is combusted to SO2 to be further converted into sulfuric acid. Methanol/turpentine as the byproducts of pulping are commonly used to replace fossil fuels in recovery boilers, lime kilns and auxiliary boilers inside the pulp mill. Particle board or plywood mills can utilize sander dust as a fuel to reduce external fuel consumption. In the future green hydrogen and its derivatives such as green methanol are likely to enter the market as major sustainable fuel alternatives for several industries and burner applications.

ANDRITZ burner systems are always specifically designed to meet customer requirements and specifications for optimum performance and to comply with all applicable local regulations and emission limits. Along with our products, ANDRITZ know-how and long experience will guide the burner system engineering, component and material selection to provide customers with the best, most cost efficient burner solution.