In addition to the choice of material for the equipment, energy-saving and ecologically compatible disposal of the brine, which is the residual salt, is vital. In order to dispose of this highly concentrated salt water safely, two ANDRITZ decanter centrifuges D4LL will be installed in the plant. They are to be used to dewater the brine. This process reduces its volume substantially and thus, provides a particularly low-cost means of disposal.

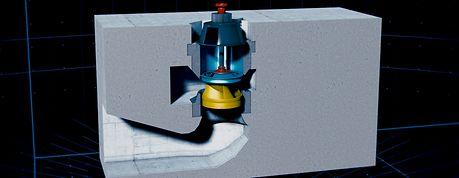

Centrifuging is a mechanical separation process in which at least two materials with different densities are separated with the aid of centrifugal forces. The decanter centrifuge D from ANDRITZ leads the market in terms of energy efficiency. As a result of the highly efficient hydraulic structure of the rotating unit, the discharge radius of the clarified liquid – the centrate – is kept to a minimum. This helps to recover the kinetic energy in the liquid and lower the energy consumption by up to 15 percent. The TurboJet weir disc, which operates according to the principle of recoil in the same way as jet engines, recovers the remaining kinetic energy from the clarified liquid. In doing so, it reduces energy consumption by up to 30%. With a regenerative drive system, the braking energy of the inner scroll against the outer drum is recovered and directed back to the main motor. This process reduces energy consumption by another five percent. Optimization by means of the latest computer-based simulation methods guarantees the lowest possible flocculent consumption, reduces wear significantly and lowers the total energy consumption once again by another two percent.