Do you have questions? Get in contact with us!

After shredding and separation of the valuable components out of RDF material, household and domestic waste, the remaining calorific value fraction is processed to substitute fuel.

ANDRITZ has long been dedicated to supporting the global shift towards landfill reduction, green energy production, and methane gas utilization. Whatever the moisture content, particle sizes, or composition of your feedstock, our broad expertise and proven technologies can help you to achieve consistently high-quality results. Our portfolio includes equipment for shredding, screening, classification, and drying and complete processes. The outcome is valuable goods, such as high-calorific RDF or SRF (Solid recovered fuel), as well as non-combustible fractions.

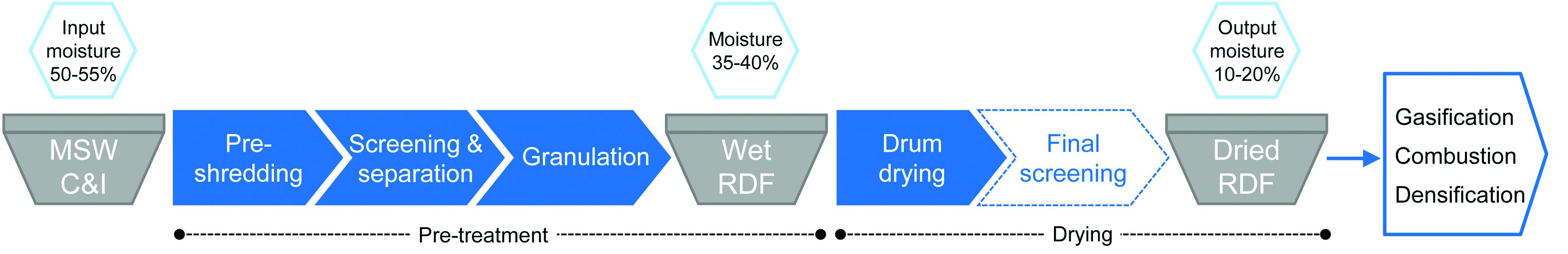

Flowsheet

Do you have questions? Get in contact with us!

Due to changing environmental legislation and the need for alternative fuels, new designs for mechanical and biological treatment of municipal solid waste (MSW) and of commercial and industrial waste (C&I) are being developed all over the world. Refuse-derived fuel (RDF) is an alternative fuel produced by shredding, sorting and dewatering the light fraction of solid waste. The objective of this concept is to obtain high-calorific and stable material. These fuels can replace fossil fuels in many applications, such as cement kiln plants, steel furnaces, or power plants. A well-proven and highly efficient drying process turns the wet RDF into a valuable energy source for further gasification, combustion, or densification.

ANDRITZ has engineered solutions for waste-to-energy systems based on many years of experience in fuel preparation processes, such as shredding, screening, and drying. Drawing on experience from numerous installations, we improve and customize the equipment for each new application. Due to our comprehensive process capabilities, ANDRITZ can serve as a single interface for your entire RDF system, offering all process steps from one source. ANDRITZ provides state-of-the-art technologies for the treatment of all types of biomass and solid waste, and has proven solutions for further processing. ANDRITZ’s process know-how is complemented by a broad range of engineering services, from basic/detail plant and process engineering, 3D planning to electrical and control engineering. ANDRITZ project managers and technical personnel continuously prove their technological and operational competence.

Do you have questions? Get in contact with us!

Turning biogenic waste residues into renowable biofuels

Turning biogenic waste residues into renowable biofuels