Refuse-derived fuel (RDF) is an alternative fuel produced by shredding, sorting and separating the light fraction of solid waste. The objective of this concept is to obtain high-calorific and stable material.

Alternative fuels: Converting trash to treasure

An increasing global population and rising energy demands are key factors driving the need for more resource-efficient waste management. One approach is to focus not only on reducing the volume of waste disposal, but also on enhancing reuse, recycling, and recovery technologies.

Efficient drying and pelleting processes convert industrial and commercial waste into alternative energy, substituting fossil fuels in

- Cement plants

- Lime kilns

- Coal-fired power plants

- Steel industry furnaces and other industries

How can landfills be transformed into energy?

Solid Recovered Fuels (SRF) are similar to RDF, but are more refined, having a lower ash content and therefore higher caloric value and lower moisture levels than RDF.

Alternative fuels often consist of combustible components found in municipal waste, such as plastics, fibers, and fabrics, and are produced by shredding, sorting, and drying the light fraction of solid waste to create a high-calorific and stable material. Transforming a highly diverse assortment of waste into new resources requires precise handling due to the varying characteristics of the source materials: moisture content, particle sizes, and bulk density. However, RDF and SRF require a consistently low moisture content to achieve a high calorific value.

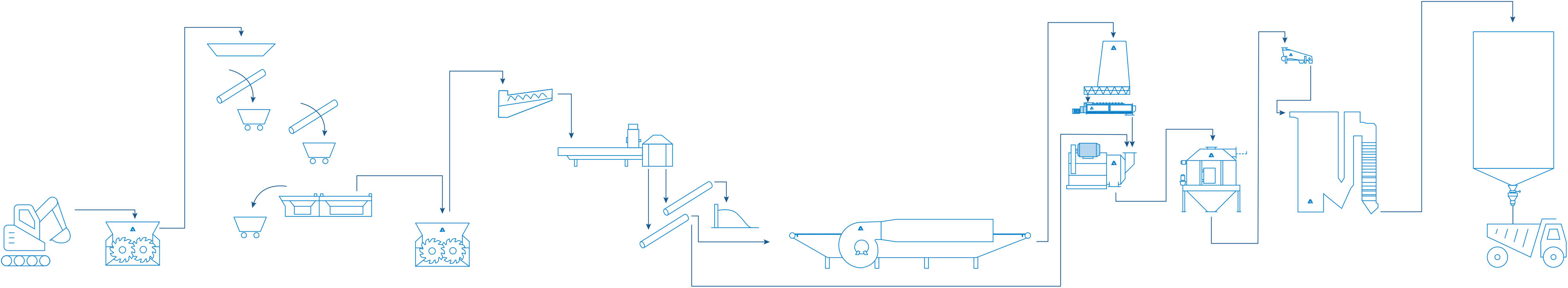

ANDRITZ supplies several proven technologies, processes, and equipment for RDF and SRF, including technologies for shredding, screening, classification, drying, and pelleting.

Benefits of waste drying:

Increased energy efficiency: Advanced drying systems boost the net caloric value of wet waste to 16-20 MJ/kg, enhancing energy efficiency. Consistent drying: ANDRITZ's specially designed feeding devices for drum and belt drying systems ensure homogeneous drying of both light and heavy particles, addressing the challenge of proper feeding and resulting in consistent and uniform drying. Effective moisture reduction: Our drying technologies, including belt dryers that can utilize low-temperature heat sources (≤90°C) and drum dryers, are capable of reducing moisture content to less than 10%, providing flexibility and effectiveness in various drying applications. |

Benefits of waste pelleting:

Cost efficient: SRF pellets represent a clean, high-density, and durable solution that significantly reduces transportation and storage costs, leading to overall operational savings.

High productivity and performance: The Paladin pellet mill series ensures high output with efficient control of the pelleting process. The robust design of the mill, equipped with twin drives, ensures smooth operation with minimal vibration, delivering reliable and long-lasting performance.

Optimal quality: The process produces a homogenous, high-density fuel that meets stringent gasification and pyrolysis standards, ensuring optimal performance in energy production.

ANDRITZ offers multiple solutions to turn solid waste into renewable energy

Experience the ART of recycling

Covering a total area of 3,600 m2, the new ANDRITZ Recycling Technology (ART) Center in Austria, allows potential customers to test a wide variety of raw materials on state-of-the-art, industrial-sized recycling machines. Equipped with innovative shredding, drying, and pelleting technology, trials can be conducted under real plant conditions. Test with your own material or with material provided by ANDRITZ, and draw on the expertise and knowledge of our recycling experts to minimize your investment risks.