Systems made from high-quality, individual fiber preparation components

A two-in-one solution - Prime cleaning performance in a single unit

The new PrimeClean TO is the latest innovation in cleaners from ANDRITZ. The “TO” designation comes from the fact that it combines two cleaning stages in one unit (two-in-one). Thanks to its innovative reject chamber design, the PrimeClean TO is ideal for removing sand and small particle debris from approach flow stock and recycled fiber processing lines at higher feed consistencies. The first systems have been sold and start-up is planned for early next year.

The PrimeClean TO was thoroughly tested at ANDRITZ's Fiber R&D Center in Austria.

The PrimeClean TO is the newest addition to the ANDRITZ family of low consistency hydro-cyclone cleaners. It is ideally suited for recycled fiber and approach flow applications with feed consistencies up to 3%.

Its ability to handle higher feed consistencies enables the PrimeClean TO to operate with less water in the stock. A considerable reduction in the volumetric flow is noticeable in the first two cleaner plant stages. This translates to a significant reduction in pumping energy, with separation efficiency remaining at the highest level, when compared to a conventional LC cleaner plant.

TWO CLEANING ZONES IN A SINGLE UNIT

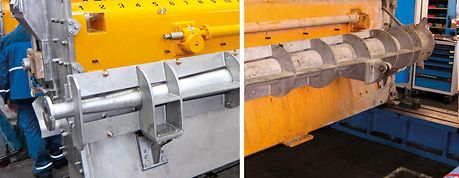

The technological cornerstone of the PrimeClean TO is its two-in-one design: a first-stage cleaner cone stacked on top of a second-stage cone with dilution water injected at the transition between the two stages. This increases separation efficiency and reduces energy consumption in a smaller physical footprint.

The design was prototyped and extensively tested at ANDRITZ R&D facilities in Finland and Austria. After proof-of-concept, commercial-scale cleaner units were installed in approach flow and OCC lines in Finnish mills. The results were impressive: superior dirt removal for paper machine approach, and excellent sand removal for OCC when compared with conventional cleaners

The two-stage PrimeClean TO can be installed in the same physical footprint (one-to-one replacement) for a conventional SC133 single-stage cleaner from ANDRITZ. This is a major benefit in rebuild and upgrade situations because mills can increase stock throughput and quality at the same time.

SMALLER IS BETTER

For hydro-cyclone style cleaners, the smaller the diameter of the separating cone, the higher the separation forces inside the cone and the higher the cleaning efficiency. The cones in the PrimeClean TO have a unique design to achieve this efficiency. The stock flow inside each small-diameter cone is uniformly directed through three chambers to efficiently separate good fibers from rejects. ANDRITZ engineers used computer-based modeling and simulation software to arrive at the optimum diameters for reaching high separation efficiencies in the cleaning zones while achieving the desired throughput, reject levels, and runnability.

There are two reject chamber options for the PrimeClean TO – one without dilution and one with ANDRITZ’s patented Multi-Injection Vortex Control (MIVC) technology to provide additional dilution water.

OPTIONS FOR REJECT DISCHARGE

The reject chambers in the PrimeClean TO have a large area to ensure stable operation and to minimize the risk of plugging. There are two options for reject discharge – one without dilution and one with ANDRITZ’s patented Multi-Injection Vortex Control (MIVC) technology. With MIVC, the reject port is equipped with a hose connection to provide additional dilution water. This is particularly beneficial in OCC and high-contaminant applications. Minimal dilution water is required with MIVC since it is utilized directly in the rejects flow without diluting the accepts flow. With MIVC, good fibers are retained, and plugging is virtually eliminated.

HIGH-TEMP AND WEAR-RESISTANT

The cleaner cones in the PrimeClean TO are made from a special OX polymer material that was developed by ANDRITZ to operate in high-temperature and/or high-wear installations. The OX material is resistant to chemicals, so the inner surface of the cone remains very clean. As an option, mills can specify that the lower cleaner cone and reject chambers can be produced from ceramic materials to further increase product life.

COLOR CODING OF PARTS

Asymmetrical cleaner parts in the PrimeClean TO (i.e., parts for the left and right sides of the cleaner bank) are produced in different colors to avoid an accidental mix-up when assembling or when performing maintenance work.

The PrimeClean TO cleaner bank with reject dilution option.

SUMMARY

In many applications, the installation of a PrimeClean TO can eliminate a bank of cleaners while ensuring the same separation efficiency. Or higher efficiencies can be achieved using less pumping energy.

The reality of a cleaning plant with a smaller footprint that can remove smaller particles from the stock and consume considerably less pumping energy when compared to a conventional LC cleaner plant is now here with the PrimeClean TO.