Efficiency and productivity are essential needs of your nonwoven production. That’s a fact! Do you want to know how you can still improve the quality of your production in terms of web uniformity & profiling while saving on raw materials plus increasing your end of line speed?

Can product uniformity be maintained in the production of nonwovens by automating the process?

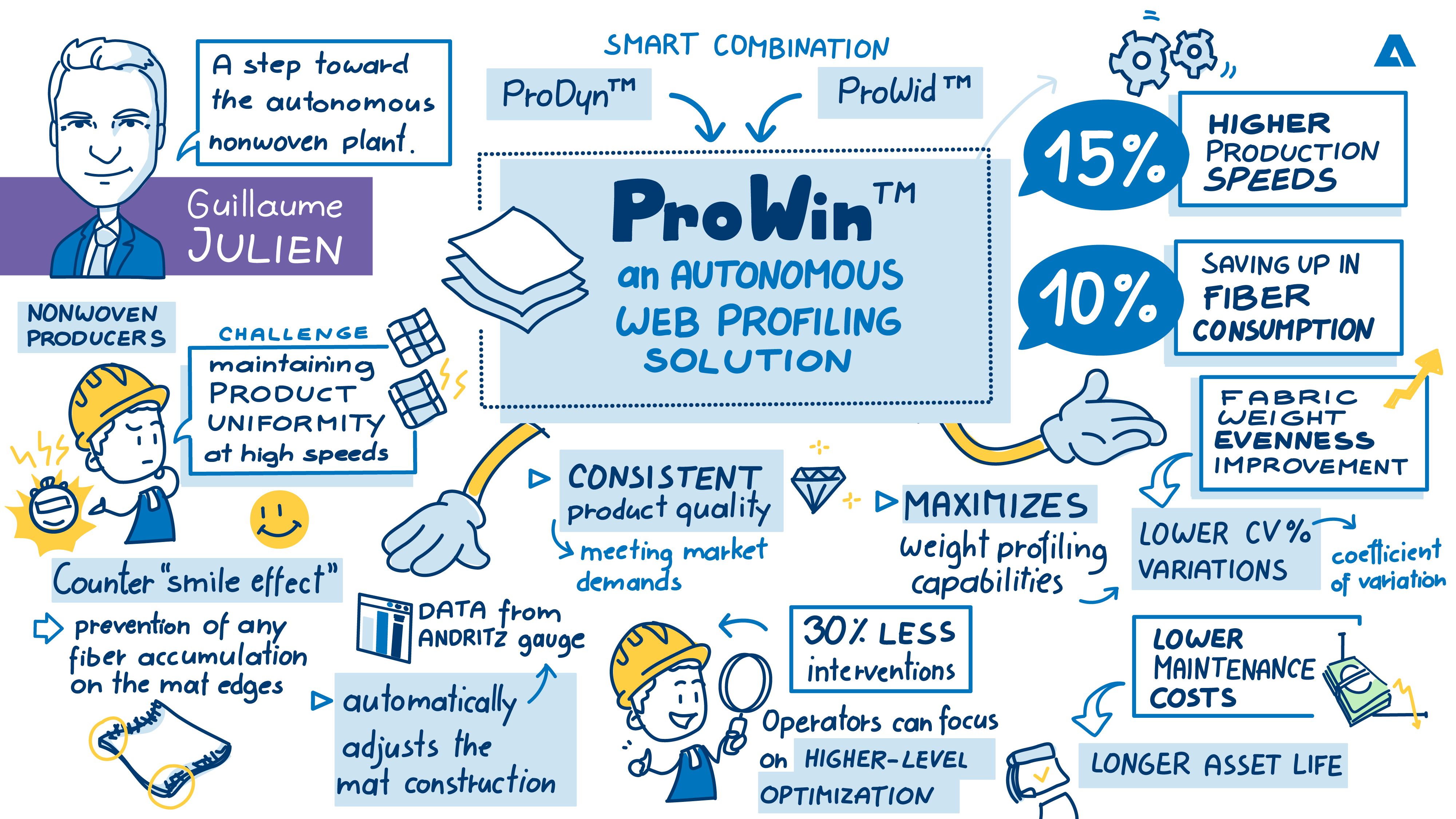

One of the toughest challenges in the production of nonwovens is maintaining product uniformity at high speeds. Issues like the "smile effect," where fiber accumulates on the edges of the mat, lead to quality losses and wasted material. Producers are also under pressure to cut costs, save fiber, and reduce manual interventions, all while meeting sustainability goals such as lowering energy usage and emissions.

The actual process of producing nonwovens can be described as similar to baking bread - but at industrial speed. Fiber mats have to be laid evenly, layer after layer, without clumping at the edges or thinning in the middle. Even a small imbalance can create wasted material, downtime, and product inconsistency. Traditionally, operators had to constantly adjust settings to avoid this, but that is all changing with autonomous control.

ANDRITZ has developed ProWin™, an autonomous web profiling solution that combines the strengths of its ProDyn™ and ProWid™ technologies, together with Advanced Process Controls systems. The results? Up to 15% faster production speeds, 10% fiber savings, more even fabric weight, and dramatically reduced operator workload.

In this podcast we talk to Guillaume Julien, Global Sales Director, Nonwoven, ANDRITZ about addressing the challenges of maintaining product uniformity at high speeds through a smart combination of technologies and automated regulation.

Season 4 / Episode #39

GUEST:

Guillaume Julien, Global Sales Director, ANDRITZ Nonwoven