“Because of the unique and patented logistic concept ANDRITZ is able to provide Yankees up to 26 ft. diameter and with a length up to 8.4 m.”

Franz Harrer,

Head of Technology Tissue, ANDRITZ

ANDRITZ first started investigations into the viability of making steel Yankees in 2007. By 2009 it had already manufactured its first one, a small, 12 ft. diameter Yankee which was sold to Saigon My Xuan Paper, Vietnam. Next was a delivery to APP’s mill in Perawang, Indonesia which was also 12 ft. in diameter.

By 2010, interest was gathering in the installation of ANDRITZ steel Yankees based on the success of the first installations, and the company began manufacturing double wide and larger Yankees, moving up to 16 ft. and then 18ft. in diameter, and by 2012 it had produced a 22 ft. version.

Fast forward to 2021 and ANDRITZ has now supplied more than 90 steel Yankees around the globe, including the installation of the world’s largest steel Yankee – 24 ft. in diameter – at Heinzel Pöls in Austria. Since the first delivery in 2009, not one of the installed Yankees as has had to be replaced, illustrating the durability and reliability of ANDRITZ steel Yankees.

Franz Harrer,

Head of Technology Tissue, ANDRITZ

Following is an interview with ANDRITZ Yankee experts, explaining the advantages of the technology for various applications in the papermaking industry. ANDRITZ experts interviewed are: Franz Harrer, Head of Technology Tissue, Riccardo Pierini, Steel Yankee Product and Customer Care Manager, and Robert Schloffer, Director Paper Machine Service

Riccardo Pierini,

Steel Yankee Product and Customer Care Manager, ANDRITZ

Harrer: In general steel Yankees are mostly used for new tissue machines and rebuilds including dry-crepe tissue but also advanced technologies such as textured and structured (TAD). The reason for that is that the Yankee is not only the heart of the tissue machine but one of the main cost drivers of the tissue production process.

Step by step, steel Yankee technology has entered other business areas, for instance ANDRITZ is an established supplier for Yankees for MG (machine glazed) machines and tobacco machines. And this is not the end of the story: drying cylinders of the pre- and after dryer section of paper and board machines can be fully made of steel as well – delivering the same benefits like the larger, single steel Yankees.

Additionally, ANDRITZ supplies Yankees to other industries, including the food manufacturing industry for specialist drying purposes.

Harrer: As a Yankee is still a mandatory component for conventional tissue machines, the number of installations is growing. We believe that steel Yankees, in particular, are showing even more significant growth as cast Yankees have their disadvantages and as sustainable, energy-efficient, and safe production is nowadays of utmost importance.

Harrer: For new machines, steel Yankees are state-of-the-art technologies based on a number of advantages for example, better drying performance and more sustainable production than cast-iron models: Steel Yankees with their higher efficiency and steam pressure, together with a shoe press that operates at high press loads offer a remarkable potential for energy reduction. Up to 24% compared to other machine configurations are possible! In combination with steam-heated hoods the saving potential is even higher.

For Yankee replacements, steel Yankees are the technology of choice. Multiple cast Yankees have a limited lifetime expectancy and therefore must be replaced. When doing such a replacement (steel instead of cast iron) one big advantage is that the new Yankee can be operated at higher pressure, thus providing enhanced performance. This performance increase can be achieved without any changes in the length of the existing dryer section.

However, one of the biggest advantages of steel Yankees is the safety aspects. The ductile material is safer in case of imperfections in the material than the brittle cast iron. Cast iron has the big disadvantage that it could explode without any indications beforehand. And there is less need for maintenance (grinding and polishing).

Robert Schloffer,

Director Paper Machine Service, ANDRITZ

Harrer: Up to now, ANDRITZ holds the world record for the largest installed steel Yankee worldwide. Because of the unique and patented logistic concept ANDRITZ is able to provide Yankees up to 26 ft. diameter and with a length up to 8.4 m.

ANDRITZ’s aim in sizing and dimensioning is to find the most efficient solution for our customers. Depending on the customers demand taking economic and ecological factors into consideration the best Yankee size and design is chosen. To guarantee best performance, every Yankee is customized.

Pierini: In terms of quality ANDRITZ focuses on the whole lifecycle. At the beginning a full understanding of the material, operating conditions and inspections through the whole lifecycle was necessary. Because of this ANDRITZ collaborated with industrial partners and universities performing detailed studies to get an overall understanding of the materials’ behaviour at high temperatures and in tough operating conditions. The outcome of this study was a comprehensive product quality and inspection plan. Actual valid pressure vessel regulations manage static pressure vessels. As the steel Yankee is dynamically loaded, more strict acceptance criteria have been introduced by ANDRITZ also considering the fatigue cycles (mechanic fracture mechanism) and not only the static loads.

ANDRITZ is proud to be the leading supplier for steel Yankees having all technologies, manufacturing and metallizing, and of course services in house. The huge benefit for the customer is to get everything from one supplier and having a partner they can trust by their side with a comprehensive understanding of papermaking, designing, sizing, manufacturing, inspection, service and operation.

Pierini: Compared to cast Yankees, steel Yankees can be manufactured with lower wall thickness thanks to the material properties of steel compared to cast iron. This provides a better heat transfer and more economic use of the steam. All in all, the consumption will be reduced, or the production increased, which finally ends up in lower CO2 emissions per ton of paper.

Pierini: ANDRITZ has all technologies around steel Yankees and their whole lifecycle in house, including:

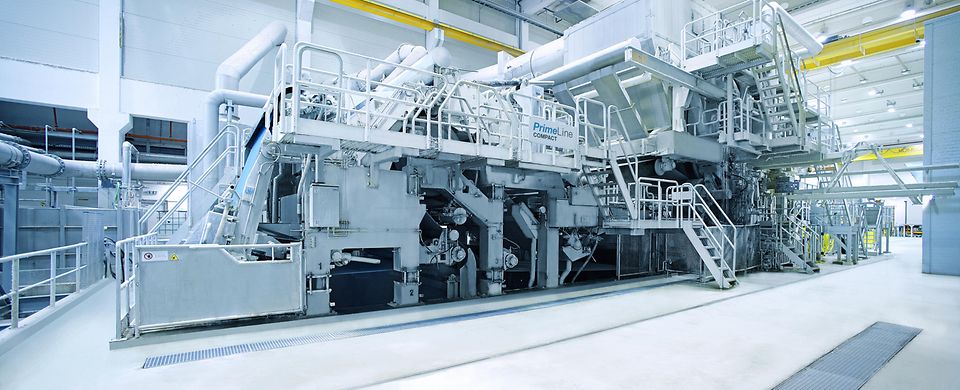

Schloffer: A well-maintained Yankee offers a high potential for improved runnability and efficient production — a remarkable competitive advantage for the customer. With our Yankee lifecycle management, we focus on the overall added value of Yankees: from calculation, to manufacturing, metallizing (PrimeCoat Stratos), operation, and optimization; no matter if the Yankee is used for tissue, paper, or tobacco production.

Hungary:

ANDRITZ steel Yankee manufacturing workshop is located in Tiszakécske on a 150,000 m2 site. Where welded structures are concerned, the company numbers among Hungary’s largest manufacturing companies. The site is equipped with the most modern manufacturing technologies for sandblasting, welding, CNC machining, surface treatment, and assembly. Over 90% of the products are exported to the European Union and the United States. The activities of ANDRITZ cover all stages from flame cutting to final assembly, for pieces weighing up to 150 tons. The company is thus capable of producing complete, fully assembled, insulated components ready for connection to other units at erection sites.

China: ANDRITZ Yankee Business Center

More than 50 references and record installations in Asia confirm that ANDRITZ is one of the leading suppliers of tissue machines, components and local services for this key market. In 2014 ANDRITZ brought the local support to another level: at ANDRITZ China, the new steel Yankee Business Center opened its doors to enable state-of-the-art steel Yankee manufacturing, local field service and quality management. With an area of 4,200 m2 the business center features the latest machinery to enable steel Yankee production and service at the highest quality level.