“Metris OPP has made a big difference in Eldorado’s performance. In a short time, we have achieved excellent results.”

Carlos Monteiro

Eldorado’s Industrial Director

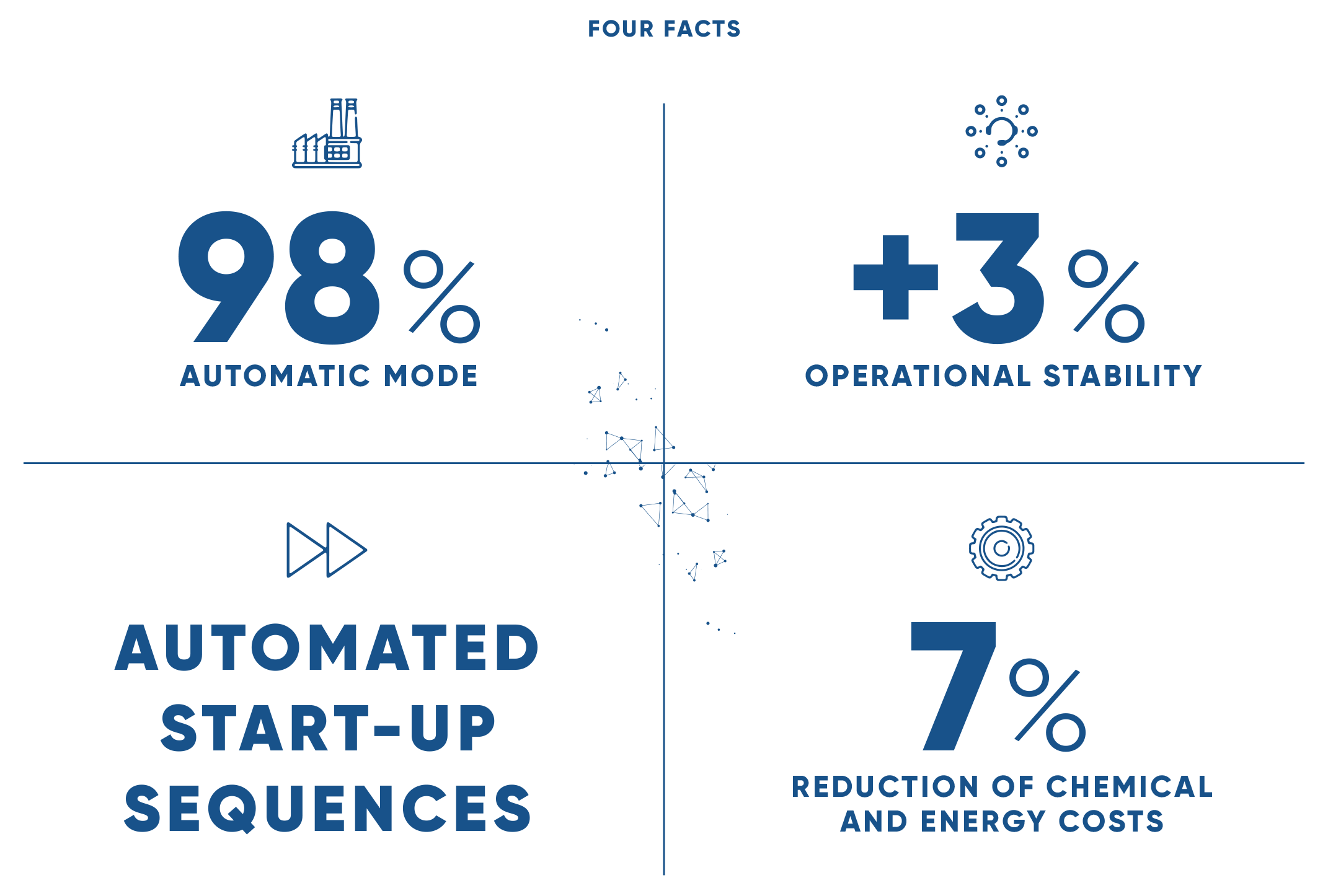

Today, the Eldorado mill runs in automatic mode 97-98% of the time, enabling Eldorado to progress from basic control to “hands off” and even “eyes off” operation.

However, operators mostly still start and stop the production process and take over when malfunctions or breakdowns occur, which accounts Tiago Garcia (Utilities DCS Operator), Douglas Freitas (Power Boiler DCS Operator), Adriano Cabral (Automation Analyst) and José Spadon Jr. (Fiber Line DCS Operator) for the remaining 2-3% of control tasks. For the rest of their shift, operators can safely turn their attention away from mundane control tasks. “By running in auto, we can re-assign operators to more highly leveraged tasks,“ Pimenta says. “If you think about it, even the best operator in the world can’t be alert and on-duty 24/7/365.

Eldorado Celulose’s senior management team (left to right): Luiz Roberto Araujo, Maintenance; Marcos Steyer, Woodyard and Chip Preparation; Murilo Sanches, Recovery, Utilities and Energy; Leonardo Pimenta, Technical Control Manager; and Marcelo Martins, Production Manager.

At the bleach plant, an automatic start-up sequence has been implemented and tested. “The operators only have to press one button, and the plant starts up by itself,” Santos says. “After the process has started, Metris OPP takes over to control bleach production. The expansion of this sequence within our autonomous mill has reaped tangible rewards already, which is why we are now developing similar start-up control for the washing processes.”

Three reliability engineers are part of the ANDRITZ- Eldorado team working on the Metris OPP project. According to Luiz Roberto Araujo, Eldorado’s Maintenance Manager, these three are supporting the mill’s culture of riskbased maintenance (RBM) by centralizing information from the process and the equipment in the same database.

It sounds simple, but the amount of work is quite challenging. ANDRITZ OPP analysts have tapped into the mill’s SAP maintenance planning software to retrieve vital information on Eldorado’s 23,000 assets in the database and combine this with process info from the DCS. The whole team is working on making this communication between the databases mutual.

“This gives us a new level of knowledge about our assets,” Araujo says. “Understanding the process is fundamental to understanding the health of our mill. Identifying the risks early prevents unplanned stoppages.” Each asset has been categorized A, B, C, or D, depending upon the critical importance of the equipment to the mill’s operations. “We monitor the risks for each asset and focus our attention on the highest-priority risks to our most critical assets,” Araujo explains. “One glance at a computer screen shows us where to focus our efforts to avoid unnecessary shutdowns.”

The result? “We’re operating at 95% overall equipment availability,” Araujo says. “That is an excellent result.”

Carlos Monteiro

Eldorado’s Industrial Director

According to Monteiro, Metris OPP has made a “big difference” in Eldorado’s performance. “We have achieved excellent results in just a short time,” he says. “Every loop in APC makes us money. Selfishly, I would prefer if no other pulp mills were to investigate Metris OPP. But even if there are some who do, we intend to keep pushing and to stay ahead.”

“I suppose there are some people who believe that the Industrial Internet of Things (IIoT) is just a marketing gimmick,” says Daniel Schuck, Vice President of Technology for ANDRITZ APO. “Maybe they said the same thing about transmitters and the early distributed control systems. But what we are doing is not pie-in-the-sky fantasy. We are using new tools to do traditional things – saving mills millions of dollars a year.”

“We might have tried to do some of this alone, but we chose to bring in an experienced partner with ANDRITZ,” Pimenta says. “They have the tools and the experience to help us reach a much higher level of performance faster. Our results show that there is a lot to be gained by extracting the hidden capacity from our assets before having to make additional capital investments.”

Leonardo Pimenta, Technical Control Manager, meets with the OPP team to discuss progress. The team consists of Eldorado process engineers, reliability engineers, and ANDRITZ OPP analysts working side-by-side.

Another project is currently underway to determine the best production mill balance at any given time. “Think of it as level control for the entire mill,” says Santos. “We are writing software to monitor all the tank levels in the mill and combine this info with key process variables. This software will be crucial in achieving a higher level of autonomy of the mill because then we will have a powerful tool that will manage production throughout the mill using real-time data.”

The mill is also working on an Augmented Reality project to help maintenance staff obtain instant information in the field simply by looking at a piece of equipment with Augmented Reality glasses. At the moment, Eldorado has made considerable progress in making checklists available for operators and maintenance people on their mobile devices.

In addition, there are Metris OPP projects to optimize ash leaching, dissolving tank TTA, lime kiln energy efficiency, and other control strategies being developed. Creation of machine learning tools, automated data analytics to predict process disruptions, and two-way-communication between Metris OPP and the SAP software of the mill are also in progress.

There are various “flavors” of Metris OPP in various plants. The one thing they have in common is that the work is performed in collaboration with mill personnel – operators, technical resources, and management.

Eldorado is unique in that a joint team was formed – ANDRITZ and Eldorado personnel -- from the very beginning and works together every day.

“You can find Eldorado process and maintenance reliability engineers and ANDRITZ OPP analysts In the same room,” Santos says. “We interact constantly, collaborating and solving problems together.”

“We have put all our efforts into the success of this project,” Monteiro says. “I don’t think there are other mills working this way with a team of committed resources on a full-time basis.”

According to Pimenta, when Eldorado decided to go with OPP, it did so in a big way. “We chose to apply all the concepts and all the technologies that OPP offers at the same time,” he says. “We didn’t want to do it in pieces, but all at the same time and as quickly as possible. That’s the Eldorado way.”

The development of autonomous pulp mills using Metris OPP is following a similar path – and Eldorado Celulose is an early adopter of this technology.

Read the development and transformation here.