- Over 50 contracts in 14 countries

- Over 50 million savings per year

- 32 million tons of production

- Over 200 experts worldwide

- 0 capital investment

The development of autonomous pulp mills using Metris OPP at Eldorado Celulose.

Life is busy. We are all busy.

We often cram too many activities into our days – both at work and at home, to the point where it can seem chaotic. At work, we are stressed due to deadlines or meetings. In our spare time – especially with the rise of social media – we spend our “free” time staring at screens, texting and tweeting.

All this “busy-ness” and activity may give the illusion that we are living life to its fullest. Yet, inside, we feel that things are not in balance. Self-help gurus come to our rescue – giving us tools to “optimize” our everyday life. The same can be true of industrial processes – all the “busy-ness” of flow rates, temperatures, pressures, speeds, inputs, and outputs. Yes, a certain chaos can ensue when things are out of balance.

The self-help gurus for industrial optimization exist as well. In most cases, they are much more effective at helping optimize a plant’s performance than the ones at the bookstore claiming they can help us get our lives back in order. However, optimization is a tricky word. The key to optimization is to “get to the root” of what it means to be “optimal” for a given process. Is it consistent quality? Lowest cost? Highest throughput? Highest availability? Lowest equipment wear? Nevertheless, once this has been defined, there are automation tools, such as Metris OPP, that will adjust inputs/outputs in real-time to achieve optimal operations at any given moment.

Not a small task. But achievable.

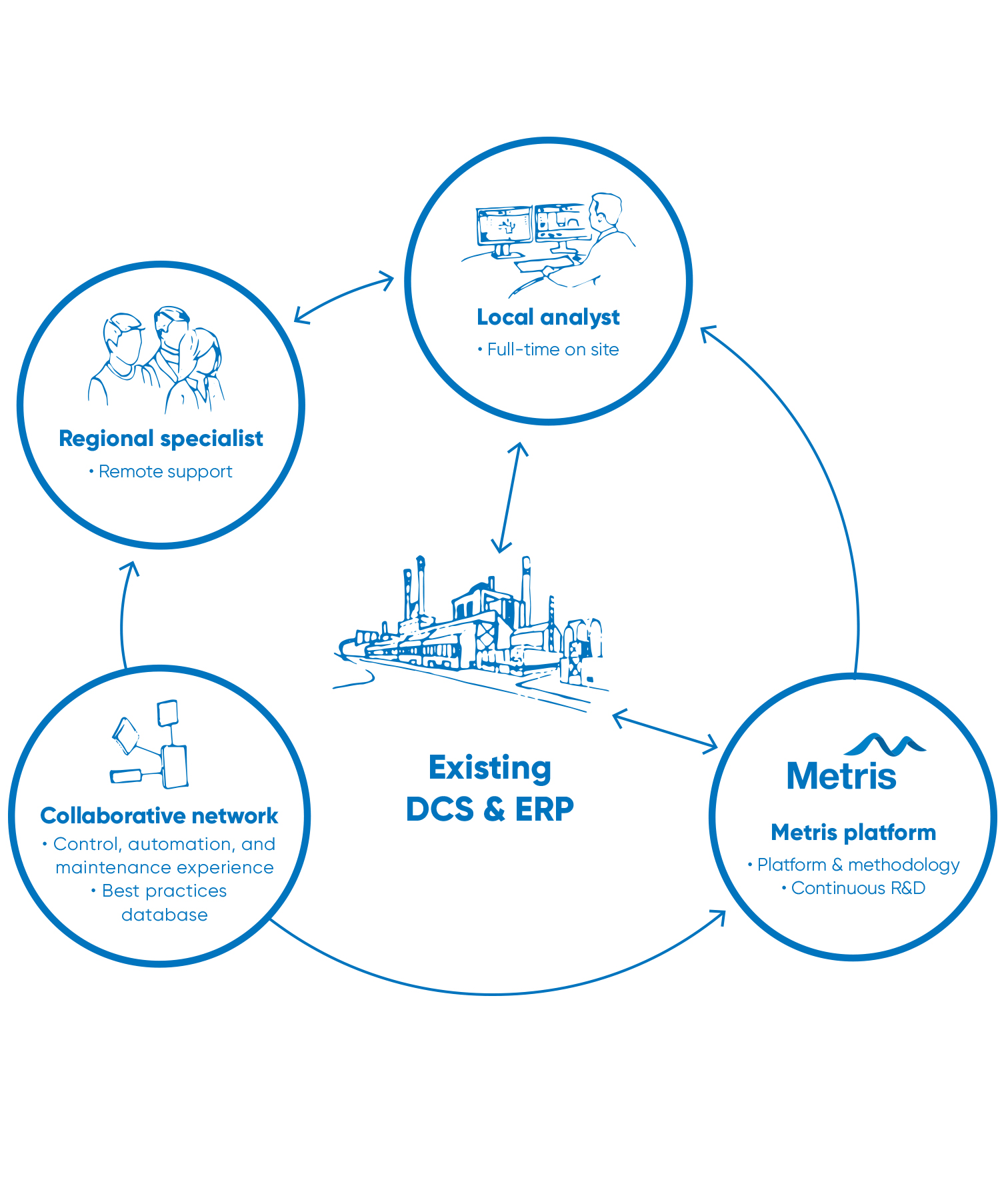

Metris OPP (Optimization of Process Performance) is an ANDRITZ service, usually performed on a longer-term contractual basis, that improves the performance of a production system. Metris OPP has helped clients worldwide save millions, with pulp mills, steel mills and chemical plants among the industries that have reaped benefits in weeks rather than years.

Metris OPP is part of the Metris family of ANDRITZ Digital Solutions. It is based on continuous developments in the three main Metris technologies – Smart Sensors, Big Data and Augmented Reality – and improves production systems by analyzing a huge amount of data collected throughout the systems.

How does Metris OPP work? The analytical software collects information from systems about each control loop, control valve, motor, and all the variables in the process. Sophisticated signal processing and statistical tools in the software identify control loops and assets that are not performing to the optimum and predict the economic impact this will have on the process. Then human expertise takes over. ANDRITZ experts work with the customers’ operations and maintenance staff to prioritize opportunities and take corrections. In some cases, it can be a simple fix such as repairing a valve. Others require analysis of the overall control objective and changing the process control strategy to eliminate off-spec production, overconsumption of chemicals and energy or sources of process variability. The result is increased operational stability and reduced

waste.

“Talk to those who can make you better than you are.” – Seneca already knew that this strategy is a reliable way of triggering improvement and working towards achieving new goals. When using Metris OPP, a client can be sure of being heard. A customer-oriented workflow focused on individual targets and KPIs is crucial, like cost savings in production, reduced energy consumption or smoother long-term operation. As soon as

the KPIs are specified, actions are taken to achieve the goal of improving the processes within the 3-month test phase. Under the basic pricing model, charges are only incurred once concrete savings have been realized. Both within the test phase and the following quarterly periods, the higher-level goals defined are analyzed, evaluated, and adapted if necessary. This approach always guarantees that the ANDRITZ experts and the customer all pull together.

Metris OPP can be compared with a tool kit and offers a variety of functionalities and apps. Tools such as the dashboard allow managers to gain a clear overview and access KPIs, balanced scorecards and project management tools. Engineers, on the other hand, can draw on OPP’s powerful data analytics tools such as data mining, statistics and power spectral density to quickly implement any efficiency modifications.

OPP is an especially powerful aid for operators and shift supervisors, for example with the Logbook. This stored user data can be utilized to enhance daily operations, find solutions to recurring problems, or train new operators. Smart controls and operator assistance facilitate an array of startup sequences, diagnostics and root cause analyses as well as adaptive set-points, multivariable predictive controls and neural networks. Regulatory control functions include control loop tuning and assessment as well as dead-time compensators and feed-forward options.

Field operators and maintenance technicians can perform more effectively with on-hand, augmented reality support. Real-time data and diagnostics coupled with remote support allow improvements to be implemented as and when they are needed. OPP also has functions that allow a malfunctioning valve or motor to be adjusted or replaced before it has had any significant negative impact on production.