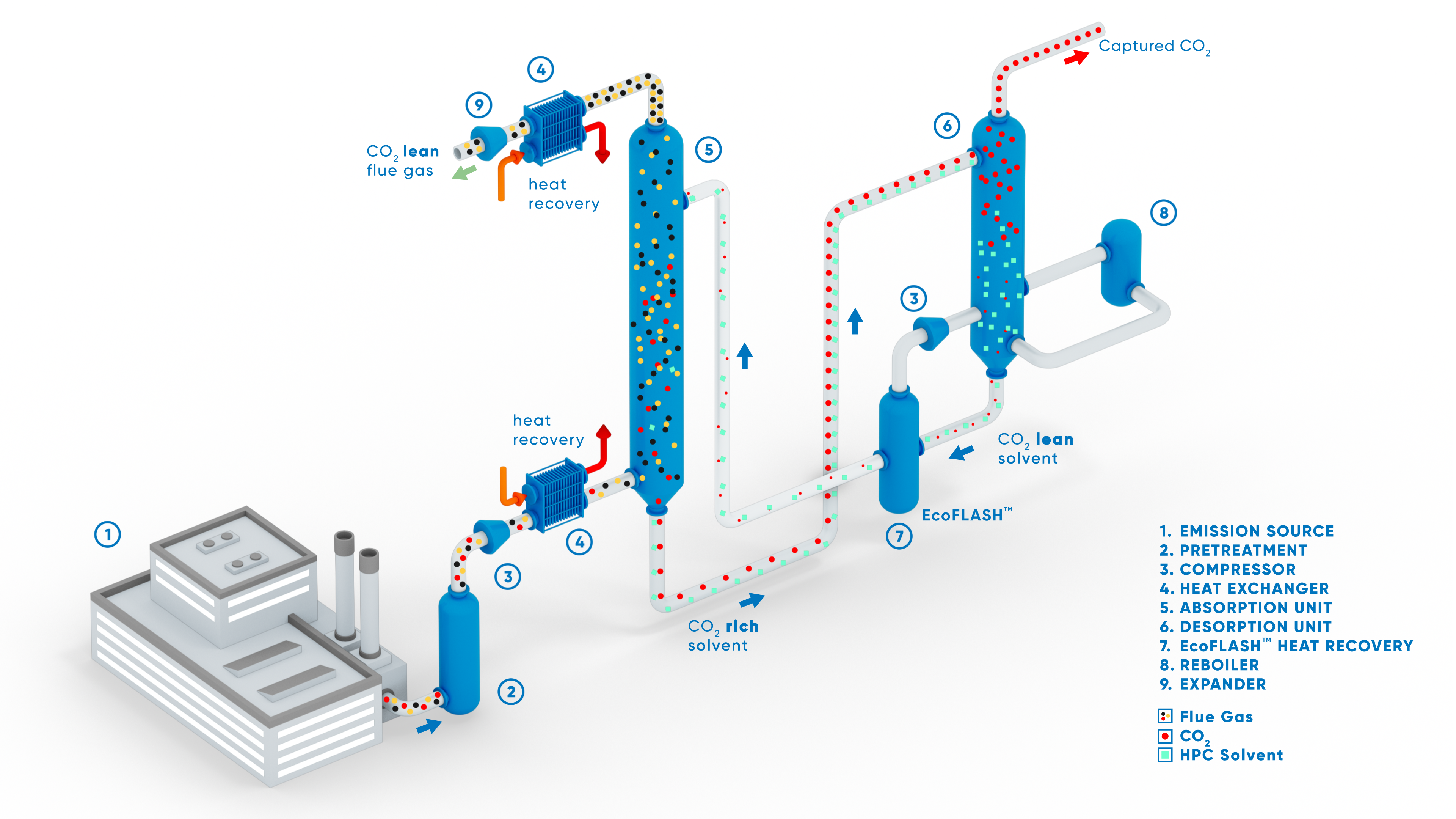

The flue gas stream, which is traditionally directed to a stack for atmospheric release, is first scrubbed of contaminants. Next, the flue gas stream is pressurized and delivered to the bottom of the Absorber Tower. At this point, the CO2 begins reaction with the liquid K2CO3 (Potassium Carbonate + Water) forming KHCO3 (Potassium Bicarbonate) while releasing heat that is captured later in the process. As the gas rises through mechanical packing in the tower, more CO2 is absorbed yielding a CO2 ‘rich’ solution prior to its exit at the bottom of the tower.

The CO2 ‘rich’ solution enters the top of the Desorber Tower and immediately undergoes a pressure drop promoting the release of CO2 and conversion of KHCO3 back to K2CO3. The introduction of steam at the bottom of the tower promotes additional CO2 release. In instances where the value of steam is high, mechanical vapor recompression configurations are available to replace the majority of heat input requirements with electrical demand. With CO2 released, the now ‘lean’ solution exits the bottom of the Desorber Tower for return to the top of the Absorber Tower and the closed loop system continues with no loss of inorganic solution.

The optional introduction of CATACARB additives to the inorganic solution enhances CO2 absorption and desorption efficiencies by more than 40% while also providing corrosion protection and reduction in tower size.

For maximum energy efficiency, heat recovery is essential to the HPC process yielding excellent economics in removal of CO2. The ANDRITZ solution maximizes heat recovery at the point of flue gas compression and via expander technology at the released CO2 stream. With the CATACARB HPC process, an EcoFLASH™ device is included for maximum energy efficiency.

Find out more