Canada - A hydropower market with long tradition

COMPACT HYDRO - More than a small solution

The COMPACT HYDRO business division of ANDRITZ HYDRO is a global leader in the market of small hydropower.

Out of the dozens of units we are delivering every year, here we present a selection of projects which showcase the latest evolution of our business.

HPP Kwalsa owned by Innergex

Mini Compact Hydro

With the acquisition of the turbine business of Hydreo Engineering (former THEE, located in Toul, France) in early 2013, the product portfolio of COMPACT HYDRO was expanded to offer competitive and reliable solutions for micro, mini and small hydropower plants. Together with the existing know-how from ANDRITZ HYDRO Jonschwil, Switzerland, in the field of small Pelton turbines, and with the specific development realized by ANDRITZ HYDRO Italy in automation and electrical systems, MINI COMPACT offers suitable and economical solutions for Kaplan and axial units (20 kW - 1,500 kW), for Francis units (up to 3,000 kW) as well as for Pelton units (up to 5,000 kW).

The launch of the MINI COMPACT range has been successful with the award of 46 contracts, totaling 65 units, in 2013. One good example of delivering a complete Water-to-Wire MINI COMPACT concept is the realization of the Molino Rizzoni hydropower plant in Italy (Hydro News 25). It involved ANDRITZ HYDRO Toul, France, for the turbine, speed increaser, and mechanical Balance-of-Plant and ANDRITZ HYDRO Schio, Italy, for the automation and the complete electrical power system.

Recent success in the development of the Water-to-Wire concept

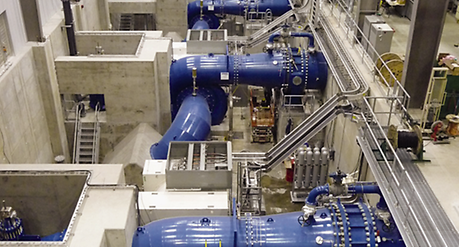

An important development focus of COMPACT HYDRO is the Water-to-Wire (W2W) concept with a single responsibility for the entire energy generation system. Two recent examples are the contracts signed with long-time customer Innergex Renewable Energy for the supply, erection, and commissioning of four horizontal Francis units (total 87 MW) for HPP Upper Lillooet and two vertical 14 MW six-jet Pelton units for HPP Boulder Creek, both located in British Columbia, Canada.

For both projects ANDRITZ HYDRO will supply the penstock manifold, turbines, generators, turbine inlet valves, energy dissipation valves (HPP Upper Lillooet only), electrical protection and control for the powerhouses and intakes. The project will be realized by ANDRITZ HYDRO Canada, France, and India.

The W2W concept offers many technical and commercial advantages to our customers. It motivated Innergex to select our solution and can be summarized as the “one supplier concept”. Having one supplier – with the qualification and experience of ANDRITZ HYDRO to deliver this large scope – optimizes the design, performance, and erection and allows our customer to minimize the technical and interface risks. This structure also supports developers to negotiate project financing with lenders, as they recognize the strength of ANDRITZ HYDRO for all elements of the scope of supply.

HPP NW Stave owned by Innergex

Compact generators

Today, the largest project using COMPACT HYDRO turbines and generators is HPP Forrest Kerr in western Canada, equipped with nine horizontal Francis units for a total installed capacity approaching 200 MW. The capacity of the units to dissipate energy at over speed and allowing a smooth ramping down of the river flow in case of load rejection from the line is only one innovative aspect. At certain times of the year, the river carries large loads of sediment. Thus critical wearing parts of the turbine, including the runner, are ceramic coated. For HPP Forrest Kerr designed, manufactured, and tested our generator factory in Bhopal, India, the nine synchronous generators. The biggest challenge was the severe shop testing of the generators, which included runaway speed tests on the shop test bed. In summer 2014 the first six units have been put in operation successfully.

Additional major hydropower projects (horizontal design) currently under execution using generators from ANDRITZ HYDRO India, are:

- McLymont Creek, Canada (3 x 26.2 MVA)

- Upper Lillooet, Canada (3 x 28.6 MVA, 1 x 10.5 MVA)

In a vertical configuration:

- Kal, India (1 x 16.6 MVA)

- Govddesåga, Norway (1 x 20 MVA)

- Sabanilla, Ecuador (2 x 17.5 MVA

- Boulder Creek, Canada (2 x 15.6 MVA).

Bulb developments

Over the last few years the Compact Axial Bulb Turbine has become a success story in the low head market for CH. The new turbine type is available in two different direct-drive generator designs, salient poles synchronous or permanent magnet (under the brand name ECOBulb™). In the recent years, ANDRITZ HYDRO has sold 12 units featuring the classic generators and 30 ECOBulbs™, with runner diameters between 1,950 mm and 3,650 mm and outputs between 1 MW and 8 MW.

Belgian utility company EDF Luminus has awarded a contract to ANDRITZ HYDRO for delivery of the complete electromechanical equipment for HPP Lixhe on the Meuse River. The existing weir with four single regulated Strafloturbines has been operating since 1979. In order to use extreme part-load operational ranges more effectively, two of the four Strafloturbines were replaced by double-regulated Bulb turbines. A challenge in this project was the placing of the new Compact Bulb turbines (runner diameter: 2,600 mm) between the existing stop logs, so that the remaining two turbines could operate without interruption during the erection phase of the new turbines.

Ottawa based company Chaudière PL has awarded ANDRITZ HYDRO a W2W contract to supply four 8 MW double-regulated ECOBulb™ units to be installed downtown on the Ottawa River. This long-term development will use the water, collected by the Ring Dam, which already feeds four hydro plants in both Quebec and Ontario. The new low visibility but high media profile power plant will be built on Chaudière Island. These units will be the most powerful Permanent Magnet units. Power converters will control the power factor and allow Low Voltage Ride Through (LVRT) conditions.

HPP Malga Bissina - electrical power system (EPS)

Power Electronics

Recently ANDRITZ HYDRO started using power electronics to adjust the electrical parameters of hydro generators and immediately recognized the advantages of this solution for specific projects and operating conditions.

For Francis and single runner regulated axial turbines, which see a large variation of net head, or with large flow related head variations, the unit speed can be adjusted optimal to the operating conditions by using power electronics. It has been implement recently on HPP Malga Bissina project in Italy and on one ECOBulb™ unit at HPP Stanley Adamson in Canada.

The use of partial power electronics allows controlling some electrical parameters, like the power factor, but mainly allows smaller units to stay connected to a weaker grid by surviving LVRT events, which no standard solution will allow.

All of the above mentioned examples of recent projects covering the extension of the range of COMPACT HYDRO in terms of technology, scope, and size and demonstrate the versatility of the business unit in adapting its structure and strategies to the effective needs of the markets and its customers. ANDRITZ HYDRO never rests on past success.

TECHNICAL DATA

Boulder Creek | |

| Output: | 2 x 14.3 MW |

| Head: | 294 m |

| Speed: | 514 rpm |

| Runner diameter: | 1,320 mm |

Chaudière | |

| Output: | 4 x 8.05 MW |

| Head: | 11.27 m |

| Speed: | 163.6 rpm |

| Runner diameter: | 3,350 mm |

Forrest Kerr | |

| Output: | 9 x 26.1 MVA / 9 x 23.9 MW |

| Voltage: | 13.8 kV |

| Head: | 103.6 m |

| Speed: | 360 rpm |

| Runner diameter: | 1,800 mm |

Lixhe | |

| Output: | 3,410 kW |

| Head: | 7.65 m |

| Speed: | 176.47 rpm |

| Runner diameter: | 2,600 mm |

Malga Bissina | |

| Output: | 8 kW – 250 kW |

| Head: | 21 m – 71 m |

| Speed: | 550 rpm – 1,000 rpm |

| Runner diameter: | 368 mm |

Molino Rizzoni | |

| Output: | 1 x 850 kW |

| Head: | 4.1 m |

| Speed: | 150 rpm |

| Runner diameter: | 2,400 mm |

Upper Lillooet | |

| Output: | 1 x 8.9 MW / 3 x 26 MW |

| Head: | 175 m |

| Speed: | 900 rpm / 600 rpm |

| Runner diameter: | 850 mm / 1,410 mm |