Exhibitions - A new experience

A new system for a known phenomenon

Auto-oscillation protection by ANDRITZ Hydro

When pumped-storage power plant Waldeck 2 was recommissioned after a shut-down the engineers detected auto-oscillation in the penstock system.

Uniper Kraftwerke GmbH / Germany has installed the systems in PSPP Waldeck 1 (one 70 MW pump turbine) and

Waldeck 2 (two ternary units each 240 MW) in 2017

This type of oscillation phenomenon tends to occur primarily when the generating units are in standstill. In most cases it is caused by a leakage, for example at the sliding ring of the spherical valve. Based on intense research, ANDRITZ Hydro has developed a new system that allows this phenomenon to be detected early on.

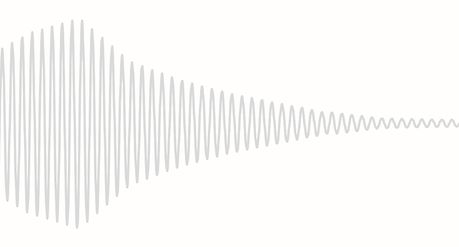

The self-excitedoscillation is the result of a pressure wave that moves along the piping and is reflected at the end points. It is typically caused by leakage with specific characteristics - the leakage volume can be described as a function of the pressure being applied. Uncharacteristically, however, increasing water pressure within the pipe reduces the leakage. Diminished discharge then creates a water hammer effect. As soon as the pressure decreases, the leakage increases again. The force of the pressure wave increases with each reflection, up to twice the static pressure.

These rare but dangerous auto-oscillation phenomena may be a consequence of different causes. For example, at Waldeck 2 in Germany the phenomenon was not caused by a leakage but by a mistake in the cabling of the control system. In most other cases auto-oscillation is a consequence of insufficient maintenance.

The increasingly fluctuating pressure in Waldeck 2 alerted the experienced ANDRITZ Hydro experts to the situation in good time. They closed the maintenance seal of the spherical valve which isolated the section that caused the oscillation in the penstock. This stopped the auto-oscillation, preventing damage to the pressure parts.

Based on this experience, ANDRITZ Hydro developed a new system that allows auto-oscillation to be detected at an early stage, so that appropriate counter-measures can be taken to protect people, machines and the immediate environment. One key advantage of the system is that it has been designed specifically for retro-fitting in existing facilities.

With the new system, ANDRITZ Hydro is providing crucial support in increasing operational safety of its customers’ facilities.

Author: Pablo Llosa