Content of HYDRO News 34.

Testing for the best – with the world’s strongest R&D rig

New high-performance turbine model test rig heading for Linz

As one of the world’s major turbine manufacturers, ANDRITZ considers it vital to maintain a leadership role in research and development. However, this requires continued investment to elevate the current turbine model testing technology to new levels. In order to remain at the top, ANDRITZ has now initiated an extensive program of R&D investment at the core of which is a new high-performance test rig.

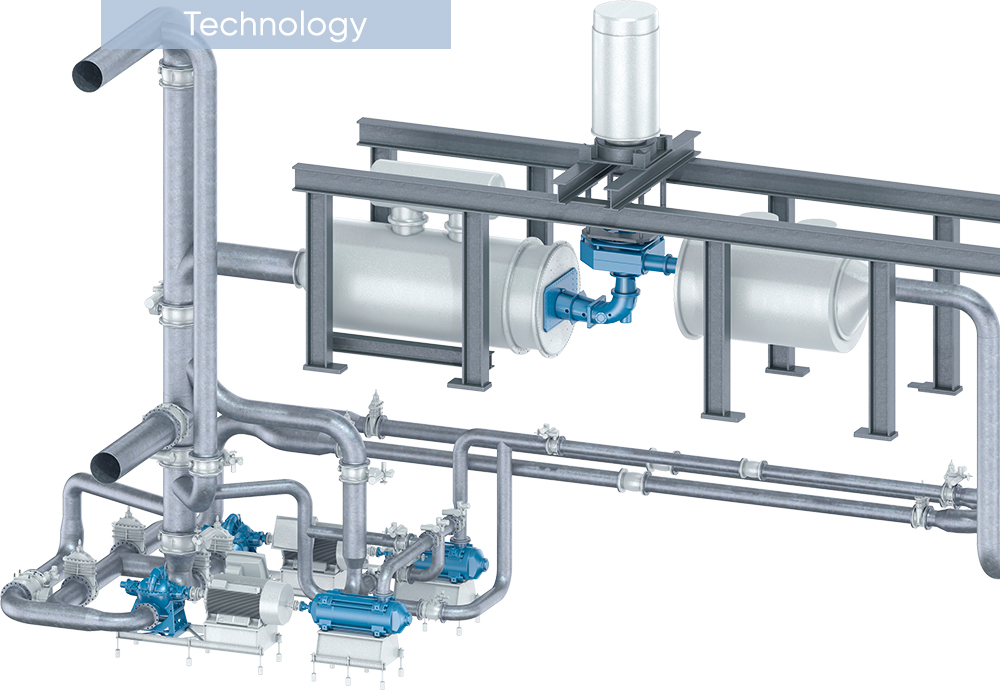

The new test rig will allow ANDRITZ to test larger turbine models and at more than twice the currently achievable head. Such a high-performance test rig will open new opportunities for research and enable further technical insights. This is especially important in key areas of technology driven by dynamic behaviour and multi-phase flows, such as pressure fluctuations, transient behaviours, and cavitation.

Due to the particularly high testing head, ANDRITZ will have new possibilities in the development of high-head Francis and pump turbine machines. This will enable ANDRITZ technology to rapidly advance, especially in key growth markets like pumped storage. An additional benefit will be that most Kaplan machines can be tested under prototype head conditions, providing new insights into the critical areas of cavitation and vortex formation.

Fully compliant with the relevant IEC standard 60193 (hydraulic turbines, storage pumps and pump turbines – Model acceptance tests), this new test rig will be the strongest universal test bed in the world. As such it will be able to test any turbine type from a low head bulb unit up to high head multi-stage pumps and will be more than twice as strong as the most powerful test rig currently available at ANDRITZ. It will enable not only research work, but also performance testing for customer acceptance tests. It will help to meet the very highest standards and the most extreme customer expectations of state-of-the-art testing technology.

The construction of the new test rig will be accompanied by an automation initiative resulting in an overall upgrade of ANDRITZ’ turbine model testing facilities. This will allow increased flexibility and faster testing. The new test rig and the automation initiative will prove beneficial for both contractual work and pure R&D. All test rigs will benefit from the full integration of ANDRITZ’ world-leading operation and maintenance system DiOMera, for example.

Due to be installed at the turbine test centre in Linz, Austria as the sixth testing line, the new test rig is expected to go into commercial operation by the end of 2021.

This substantial investment once again illustrates ANDRITZ’ on-going commitment to leading research and development, particularly in areas related to key markets such as pumps and pump turbines.

Benefits

- Strong commitment to the pump and pumped storage market

- Strong commitment to a leadership role in research and development

- Major upgrade and modernization of testing facilities

Performance data

- Maximum testing head: 250 m

- Maximum discharge: 1.75 m3/s

- Maximum testing power: 1.25 MW

- Maximum torque: 6,000 Nm

Author: Peter Grafenberger