"Supplying all six hydraulic units with a single penstock, at Dinorwig the role of the main inlet valves is of upmost importance for the maintenance of the turbine units."

Realizing national energy ambitions - Laùca, Angola

As part of a major rehabilitation and modernization project, ANDRITZ is supplying six new Main Inlet Valves (MIV) for one of Europe’s largest pumped storage projects – Dinorwig.

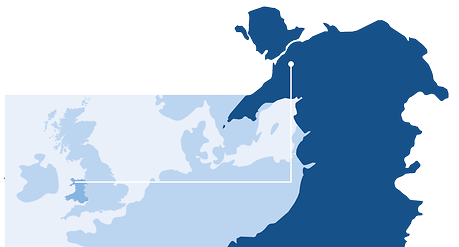

Located under an abandoned slate quarry in Elidir mountain near Llanberis in North Wales in the UK, Dinorwig pumped storage plant (PSP) has a capacity of about 1,728 MW, making it one of the biggest pumped storage plants in the world. The station complex consists of a series of caverns excavated within the slate mountain and the main cavern is considered to be the biggest man-made cavern in Europe. These caverns house the mechanical and electrical equipment, as well as operational rooms including the control room.

Fully commissioned in 1983 after a construction period of 10 years, the plant provides balancing services, including reserve and response, for the UK grid system and plays a vital role in the safeguarding of the national grid.

Dinorwig pumped storage plant has a capacity of some 1,728 MW, making it one of the largest pumped storage plants in the world.

Power at the Dinorwig complex is generated by six vertical reversible Francis-type pump turbines, each rated at 330 MVA. The exceptional characteristics of the PSP complex can also be found in the configuration of the hydraulic system. With a maximum gross head of 546.7 m between the upper and lower reservoir, the plant features a single concrete lined pressure shaft tunnel with a diameter of up to 10.5 m. A high-pressure manifold divides this tunnel into six concrete lined branches to serve each machine. A steel shaft lining and a reduction in the shaft diameter to that of the MIV begin shortly before reaching the underground station complex.

Main inlet valves fulfill various important tasks in hydropower applications. From ensuring safety in powerhouses to tightly sealing waterways for maintenance on hydraulic machinery, they have to cope with a lot of conditions and need to be resilient for the intended duty at all times.

However, when mechanical components of this importance are approaching the end of the design life, replacement or rehabilitation is mandatory.

As all six hydraulic units are supplied by a single hydraulic system and six penstrocks, at Dinorwig the role of the main inlet valves is of utmost importance for the maintenance of the turbine units. They are the only point of isolation between the pump turbine and high-pressure penstock. Simultaneously, this implies that none of the main inlet valves can be replaced without shutting the plant down and draining the entire 1,728 MW complex. Consequently, the operator is extremely focused on the reliability of critical, non-replaceable components and efficient maintainability of MIV components. Since commissioning, the hydraulic system upstream of the main inlet valves has never been fully drained down.

Nonetheless, after nearly 40 years of operation, the main mechanical components of the MIVs are approaching the end of the design life. Rehabilitation of the MIVs or partial replacement of components was not possible for technical and business reasons. Consequently, international technology group ANDRITZ received an order for the supply of six new spherical valves. The ANDRITZ scope of supply comprises the design, manufacture, supply, installation, and commissioning of six spherical valves including governors.

Existing valve in Dinorwig PSP

This contract was placed by First Hydro Company, one of the UK’s most dynamic electricity generators and which is responsible for the management and operation of the pumped storage plants at Dinorwig and Ffestiniog in the Snowdonia region of North Wales. First Hydro Company is itself owned 75% by ENGIE and 25% by Brookfield.

The outstanding characteristics of this power plant complex with its particular boundary conditions make this project special for both the pumped storage plant owner and the valve supplier, ANDRITZ. Furthermore, the ambitious project timetable foresees the installation of the first two valves in mid-2023, and the remaining four in mid-2025. This can only be achieved through close cooperation and collaboration.

The new MIV will be equipped with a more robust and larger main bearing, resulting in a re-evaluation of the drive concept.

"Supplying all six hydraulic units with a single penstock, at Dinorwig the role of the main inlet valves is of upmost importance for the maintenance of the turbine units."

The six MIV’s at Dinorwig have a nominal diameter of 2.5 m and are of spherical valve type. In combination with a design pressure of 80 bar, the operating conditions of the valves can be classified as rather demanding. Clearly, they are not an off-the-shelf valve unit. The original equipment was supplied by Boving, which is now part of ANDRITZ.

Each of the existing valves is equipped with a counterweight and is capable of being opened from a fully closed position within 10 seconds. As might be expected, the valves are executed in a rather robust manner with a core weight of some 150 t. However, the main bearings were not designed sufficiently to the task and faced some issues. This facilitated the decision to fully replace all six units instead of choosing a rehabilitation or partial replacement approach.

The new MIV will be equipped with a more robust and larger main bearing, resulting in a re-evaluation of the drive concept. Double oil-controlled servomotors instead of counterweights reduce overall dynamic load, directly mounted servomotors instead of floor anchored ones avoid time-consuming civil works. The corresponding oil control and supply concept is specifically designed to reduce the amount of oil used during movement, ensuring not only safe operation but also considering modern operation requirements while guaranteeing the MIV opening time.

For the replacement valves the following mandatory minimum requirements are in place

"The new MIVs of Dinorwig are the first spherical valves of ANDRITZ, which are intended for condition monitoring right from the beginning."

The new MIVs of Dinorwig are the first spherical valves of ANDRITZ, which are intended for condition monitoring right from the beginning. Through integration of additional sensors in the mechanical, oil and water hydraulic system, a condition monitoring of the equipment will be enabled. A modern local SCADA-system and the integration to the ANDRITZ Metris DiOMera platform are key to enabling condition-based or predictive maintenance of components. Regular processing of the evaluated data and information provided by ANDRITZ to the customer helps to prevent a system failure and extend its service life through specifc measures.

To meet all these core requirements, the overall concept must be evaluated by both the customer/operator and the supplier, bringing together operational and maintenance experience and design know-how from the equipment manufacturer. In order to complete this technically and commercially demanding project in a timely manner and in a way that is acceptable to both parties, coordination from the earliest stages of the project was of utmost importance. Using this collaborative approach, targets could be defined at an early stage and corresponding concepts developed in advance of the contract signature.

ANDRITZ is very honored to be awarded this key contract for this important pumped storage plant. With our extensive experience of spherical valves and pumped storage technology, ANDRITZ is committed to supply the new main inlet valves for Dinorwig in a timely fashion and to the utmost satisfaction of the customer. In doing so, Dinorwig will continue to fulfill its vital role in maintaining the UK’s national electricity system for decades to come.

Total output: | 1,728 MW | |

Head: | 546.7 m |

Author: Benjamin Roelle