Ohau A - New Zealand

Concrete Volute Pumps

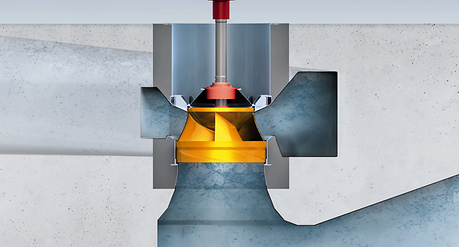

Concrete volute pumps are vertical volute pumps whose casing is made of concrete. Using concrete volutes is a well-known technology which has been applied for more than a century for Kaplan turbines.

Concrete volute pumps are vertical volute pumps whose casing is made of concrete. Using concrete volutes is a well-known technology which has been applied for more than a century for Kaplan turbines. In the pumps sector it is currently not a commonly used technology, but has many advantages for large discharge and low head applications. The demand for exactly those features for flood control pumping stations is increasing, especially in Southeast Asia, where extreme weather conditions are causing a lot of infrastructure damage and loss of life.

The concrete volute pump’s advantages are immense for those applications in comparison to commonly used vertical line shaft pumps. The main feature of the concrete volute pump is the very compact, simple and rigid design which leads to lower investment costs. To ensure optimal hydraulic performance as well as simple geometries for the civil works, ANDRITZ HYDRO has conducted specialist development of the inlet bend and spiral with CFD calculations and model tests, leading to a very high efficiency.

ANDRITZ HYDRO offers three different procedures for the civil construction of the concrete volute pump. The chosen construction procedure of the spiral depends on the number and size of the pumps as well as the medium to be pumped (fresh, brackish or salt water).

ANDRITZ HYDRO has dealt extensively with these topics to give customers the best possible solution for every purpose.

Prefabricated elements

In-situ casting

Steel liner

The spiral is split into segments, which get poured in a concrete factory and are erected on-site. The final fixing is done by a poured layer of concrete on the outside of the elements.

In-situ casting

A wooden formwork is placed on-site, reinforcement bars are positioned and the surrounding concrete is poured. After setting of the concrete, the formwork is pulled out and can be reused several times.

Steel liner

The steel liner, stiffened to avoid any deformations during pouring of the concrete, is positioned. After concreting, the stiffening is removed and the steel liner remains in the volute. The spiral surface consists therefore of steel and not of concrete.