"Our declared goal for the new development was no “me-too”."

Fritz Kopin

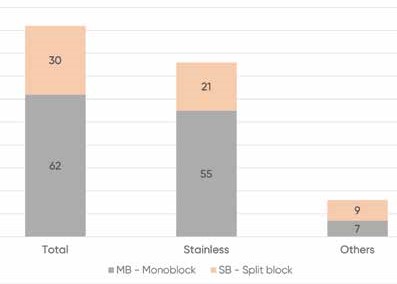

Basically, the cold rolling market for stainless steel has been divided into two competing design paradigms: the monoblock and the four column design. A market analysis of the CRMs sold for stainless steel applications in the markets accessible to us for the period of 2000-2015 shows that, out of 76 sold mills, 72% were monoblocks. With regard to another application in a narrower width – where the four column design (a split block design from ANDRITZ) has advantages due to its tilting mode – out of 16 sold mills, 56% are mills with a split block design.

20hi since 2000 by design

our current design approach allows us to serve only 33% of the market. If we consider that a lot of projects, especially in China, are built by local suppliers in markets that we consider inaccessible, the distribution of the monoblock design is much greater, as these mills are only monoblock mills. In addition, some of our competitors have developed solutions that are comparable to our four column design.

As already mentioned, if you choose a mill with the monoblock or four column mill design, the decision doesn’t really depend on the capabilities of the mill – it is often simply based on a gut feeling.

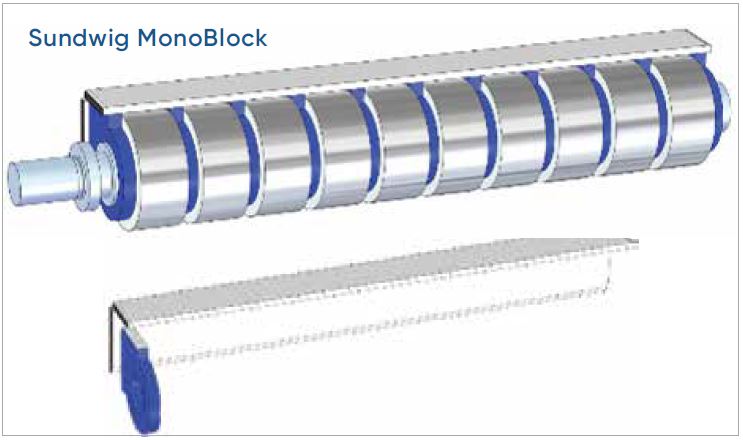

In 2016 we decided to develop the "Sundwig MonoBlock". Here, it was important not to develop a “me too” monoblock – our aim was to develop the next evolutionary step: THE BEST MONOBLOCK EVER, combining numerous features of our four-column mill in a monoblock housing.

The kick-off meeting for the R&D project started on August 2, 2016 – and the goal was to be ready to provide quotes in 2017. Alongside the goal of selling the first “Best MonoBlock ever”, another of our key goals was to become a player in the revamp project business for existing monoblock mills.

Fritz Kopin

The Sundwig MonoBlock could represent the next level in the monoblock evolution as it is better equipped to meet the market requirements. The main technical advances are

as follows:

The automated roll change has been a triedand-v tested feature of almost all new Sundwig mills over the last couple of decades. A roll change robot allows full automation – a great improvement, for example, on the clumsy, heavy, semi-automated equipment of a roll change car, which still requires workers to put their hands on the greasy rolls. So the full automation makes the workplace much more attractive and, therefore, also greatly improves the employer value proposition for steel mill operators. In addition, valuable workers can focus on doing more value-added work, thereby increasing labor productivity. Faster roll changes will enable greater flexibility in the production program, thereby allowing the operator to address smaller lots than before and enlarging the accessible market. Beside these advantages also the work place will be safer, as all manual activities increase the risk of an accident.

The same purpose of higher flexibility is also pursued by a faster gap opening. Simulations have shown that the gap opening is 3 times faster.

Automated roll change robot

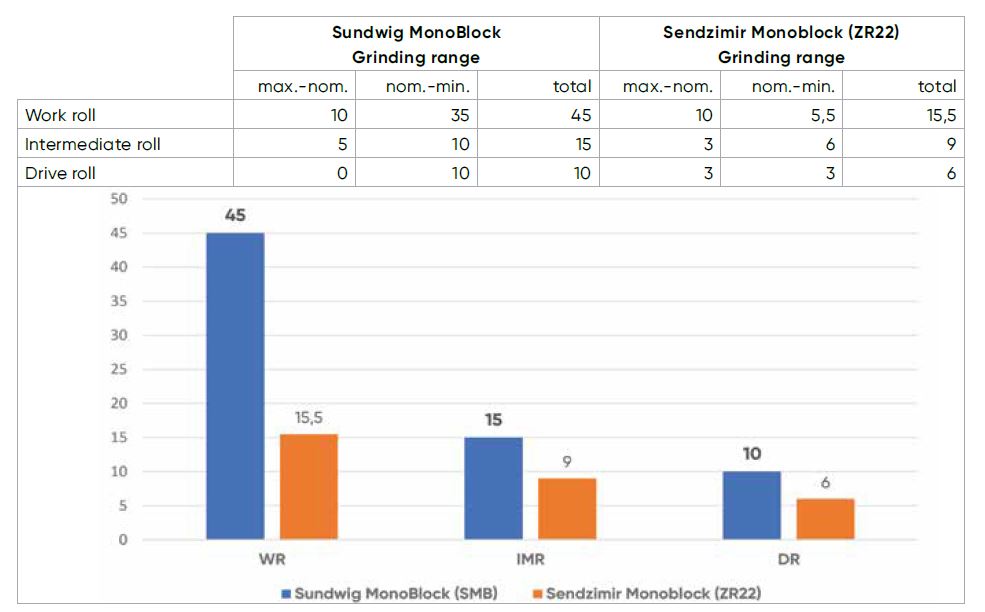

In addition, the rolls need to be changed less often thanks to a much higher grinding range. While the work roll of the conventional Monoblock still has a grinding range of 15.5 mm, that of the Sundwig MonoBlock will be 25 mm. This is still a lot less than the SFC with 45 mm, but it is certainly an improvement on 62%. Moreover, the Sundwig MonoBlock has substantial advantages for all other rolls. Every steel mill operator will immediately realize that this has a strong financial impact.

The fourth advantage of the Sundwig MonoBlock is its cheaper support shafts with easy assembly for backup rolls. The shaft assembly is obviously simpler and also no longer requires the expensive teflon rings of the conventional Monoblock design.

Roll grinding range of the Sundwig MonoBlock versus conventional Monoblock

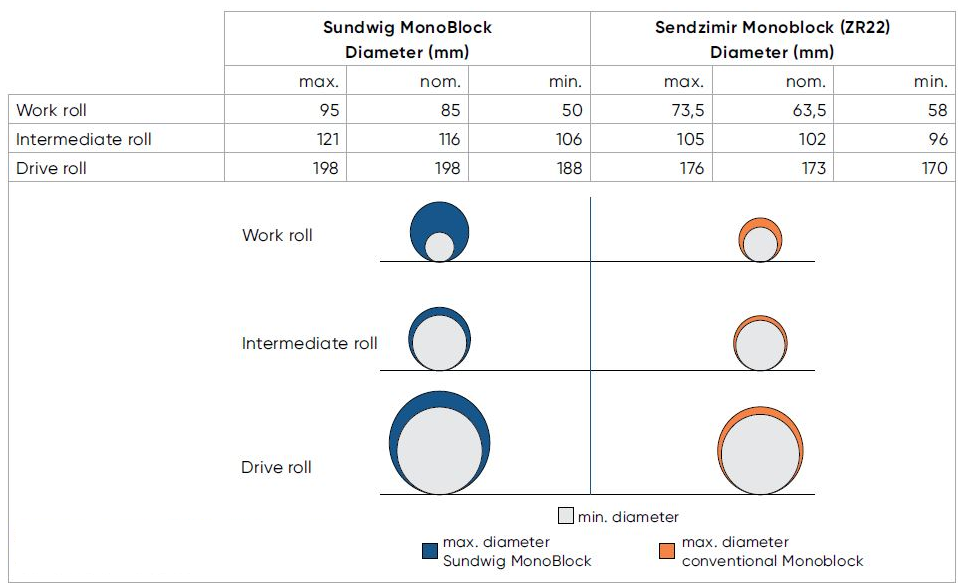

Diameter range Sundwig MonoBlock versus conventional Monoblock

Finally, the Sundwig MonoBlock will retain the proven stability and bending performance of the Monoblock while improving heat transfer by up to 30%. This is accomplished through the design of the nozzle plate.

Guido Burgel

The technical advances of the Sundwig MonoBlock lead to economic benefits for the steel mill operator. The extent to which an operator can increase revenues or cut costs will of course depend on the specific situation. Nonetheless, two calculations are provided to illustrate the order of magnitude of the change.

Comparison of the Sundwig MonoBlock and conventional Monoblock support shafts

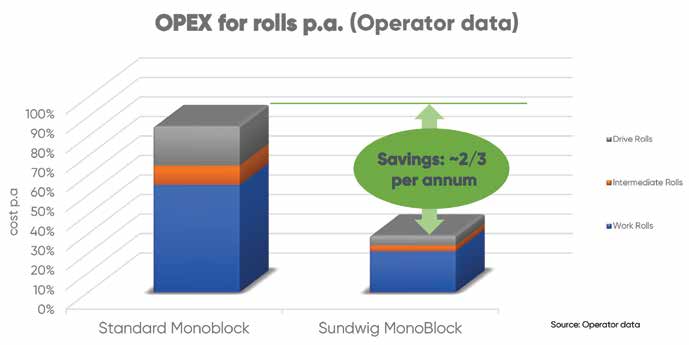

We have used the data provided by one steel mill operator to calculate the improvement in OPEX resulting from the improved roll grinding range and backup roll design. It turned out to be a staggering reduction of up to 66%. The lion’s share of this saving pertains to the work roll, but the costs of other rolls are also more than halved. This figure would be even higher if the faster gap opening was monetarized.

The second major driver of economic benefits for the steel mill operator is the improvement of the heat transfer, which directly translates into a 30% reduction in rolling oil for the same production program. The operator data provided for the conventional Monoblock comprised an oil supply to the mill of 12,000 liters per minute with a filtration rate of 13,700 l/min. Our simulation showed that the Sundwig MonoBlock will only require an oil supply to the mill of 9,600 l/min. with a filtration rate of 12,000 l/min. So the need for pumping oil to the mill will be reduced by 2,200 l/min. at 6 bar, while the filtration rate will be reduced by 1,700 l/min at 2 bar. Based on an energy cost of €0.1/kWh and an operating time of 7,200 hours p.a., the steel mill operator will save roughly € 20,000 p.a.

Since the inception of the Sundwig Four Column (SFC) housing design, the cold rolling technology is divided into a high end and a standard production end of the market. The performance parameters of the Sundwig Four Column mills are unrivalled. So if a steel mill operator makes the strategic decision to move up to the high end of the stainless steel milling market, they will need the flexibility, quality, and cost efficiency of an SFC to meet market demand.

In the standard cold rolling market, however, the 2019 Sundwig MonoBlock proves to be the “Best Monoblock ever” with substantial economic benefits for the steel mill operator. No matter how the stainless steel market conditions change, it will certainly be imperative to deploy the leading technology in order to thrive in a commodity market. So operators should not hesitate and wait for signs of a market recovery if they want to have a sufficiently profitable future in standard steel qualities.

Still, history has shown in many markets that the best product does not automatically win the race. This is partly due to investment policies, and may partly also be based on switching and service costs. With regard to investment policies, mill operators will no longer be forced to switch technology in their quest to obtain performance improvements in standard production. Now they can stay true to their decision to use only the monoblock design. Operators considering the switching cost should not find many disadvantages in using the Sundwig MonoBlock either, as all existing backup roll bearings can still be used. Thus a large proportion of the switching cost is already taken care of. And finally, the global Sundwig servicev organization should discern support issues which may otherwise inhibit the operator from moving to the next level in the monoblock evolution. So, considering the evidence of substantial technical advances, attractive economic benefits, and the lack of any significant barrier to switching, the Sundwig MonoBlock is predicted to be a potential game changer in the standard cold rolling market.

In 2017, we completed the development of the Sundwig MonoBlock and created a well-balanced marketing and communication strategy. Due to the fact that the stainless steel market had been in decline for several years, we decided to wait with the market launch until the market picks up again. In October 2019, we officially presented our new Sundwig MonoBlock at the ESSC & DUPLEX 2019 (European Stainless Steel Conference & European Duplex Stainless Steel Conference). In March 2023, we sold our first “Sundwig MonoBlock”.

Difference in OPEX between the Sundwig Monoblock and the conventional Monoblock

Guido Burgel