ANDRITZ (China) Ltd. Wuxi Branch

CHINA

The neXline spunlace aXcess range enables to enter the nonwoven market in capacity range up to 12,000t/a. Its proven concept encompasses opening and blending equipment, carding systems, hydroentanglement units, and through-air dryers especially designed to produce a wide range of spunlace fabrics at low operating costs.

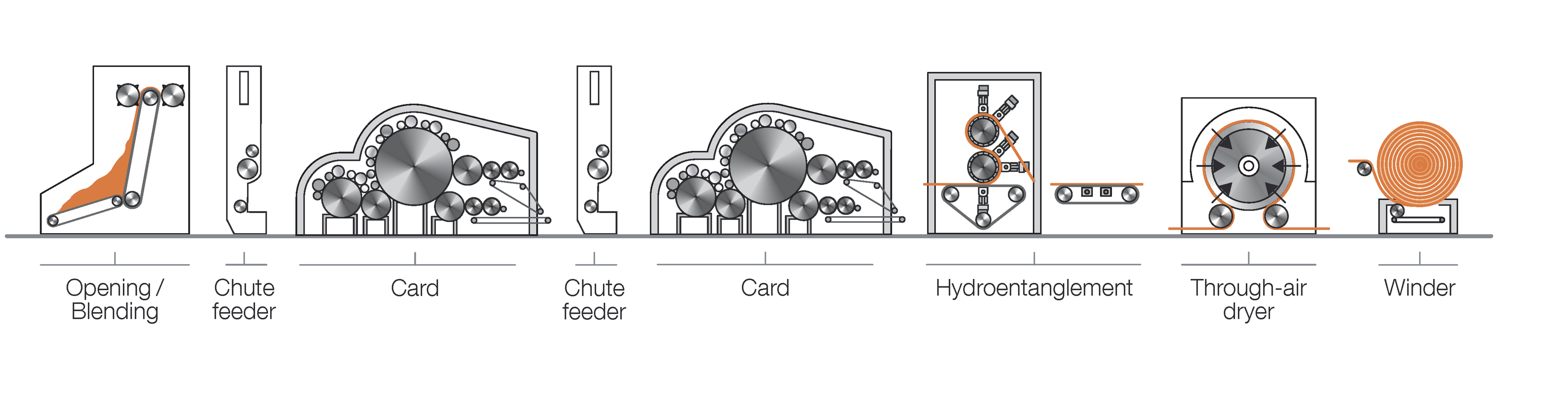

The nexline spunlace aXcess has been specially designed for growing markets. Thanks to the combination of the robust CA22/25 cards and the innovative Jetlace Avantage hydroentanglement system, we can now provide a new process for capacities up to 5,500 t/a. It is the perfect solution for newcomers producing lightweight spunlace fabrics.

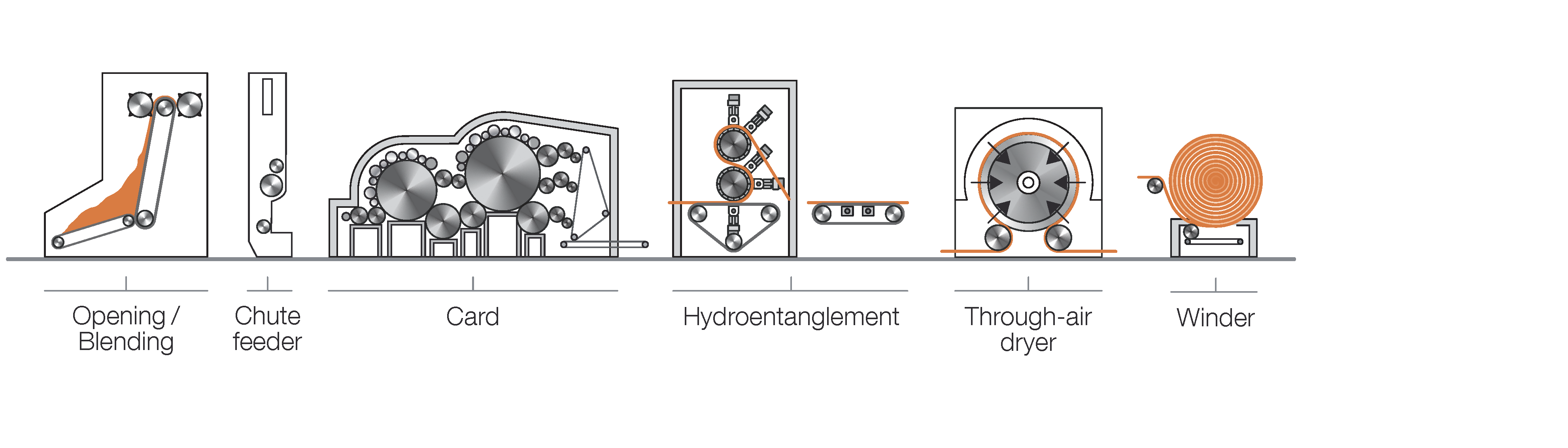

ANDRITZ set a new milestone in the spunlace industry with the newly configured nexline spunlace aXcess for lightweight fabrics. This complete line is equipped with only one VarioWeb in-line card with three doffers in combination with the well-known Jetlace Avantage hydroentanglement unit and the neXdry Avantage dryer. Manufacturers can now produce state-of-the-art spunlace fabrics with perfect web uniformity.

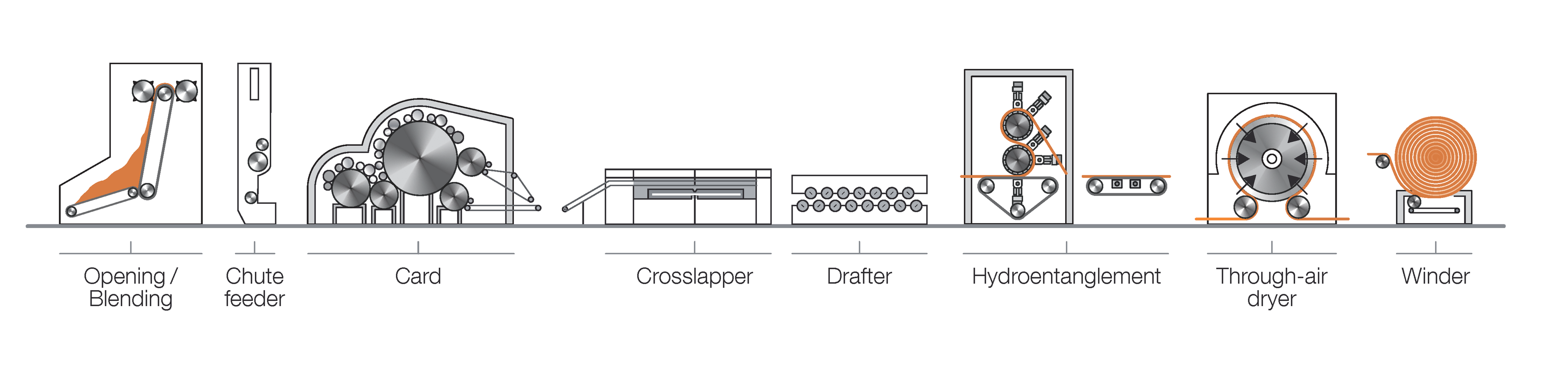

The nexline spunlace aXcess, including the Opening/Blending APC, a CA21/22, a profile crosslapper, a Jetlace Avantage hydroentanglement unit and the neXdry Avantage dryer is especially designed for the production of nonwovens with various mechanical properties, like a balanced MD:CD (machine direction, cross direction) ratio, is demanded by hygiene (face masks), coating substrates, automotive and filtration applications.