Tajikistan, Nurek

Valves

Valves for hydraulic power projects are installed for safety, maintenance, and shut-off, as well as for flow and pressure regulation.

Worldwide ANDRITZ Hydro has installed

- Butterfly valves up to a diameter of 6,000 mm and design pressure of 64 bar

- Cone valves up to a diameter of 2,200 mm and design pressure of 64 bar

- Spherical valves up to a diameter of 3,300 mm and design pressure of 200 bar

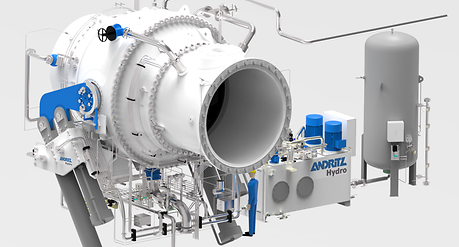

Butterfly valves

Butterfly valves are equipped with either a lens type or a lattice door (through-flow) type. These door types were optimized in model tests to achieve a minimum flow head loss coefficient. This type of valve is mainly used as safety valve, turbine inlet valve, and pump valve for low to medium design pressures.

They are operated by oil hydraulic systems for opening and closing, or by closing weight and hydraulic pressure for opening. For turbine inlet valves, oil pressure can also be taken from the governor hydraulic oil system. The sealing system is of flexible, adjustable rubber/metal type to reduce leakage to a minimum.

The lattice door type valves may also be equipped with a maintenance seal. The hydraulic and electric/electronic control system is part of the delivery. Auxiliary equipment such as bypass, air and vacuum valve, pipe rupture device, and connecting pipes are usually within the scope of supply. Water flow through the valve is possible in both directions.

Cone valves

Cone valves are installed for flow regulation from 0 to 100%, for energy dissipation, and as pressure relief valves. They are often installed in combination with an upstream guard valve (e.g. butterfly valve) for maintenance and emergency shut-down purposes.

Cone valves allow high discharge flows at high water pressures. The valves are controlled by an oil-hydraulic or electromechanical operator. Flow is only possible in one direction. Local operator instrumentation, control system (hydraulic, electric, and electronic), discharge liner, and connecting pipes are part of the valve supply.

Spherical valves

This type of valve has a minimum head loss due to a completely free through-flow. They are usually installed as high-pressure turbine inlet and pump valves and equipped with controlled service and maintenance sealing. Flow is possible in both directions.

The control system is operated by oil-hydraulic pressure, or by the water pressure system, or both, i.e. opening by oil pressure and closing by water pressure. The water for the valve control system can be taken from the upstream side. Oil pressure for the control system can also be supplied from the hydraulic turbine governor oil system. Bypass, hydraulic, and electric control systems, as well as connecting pipes are usually part of the supply.