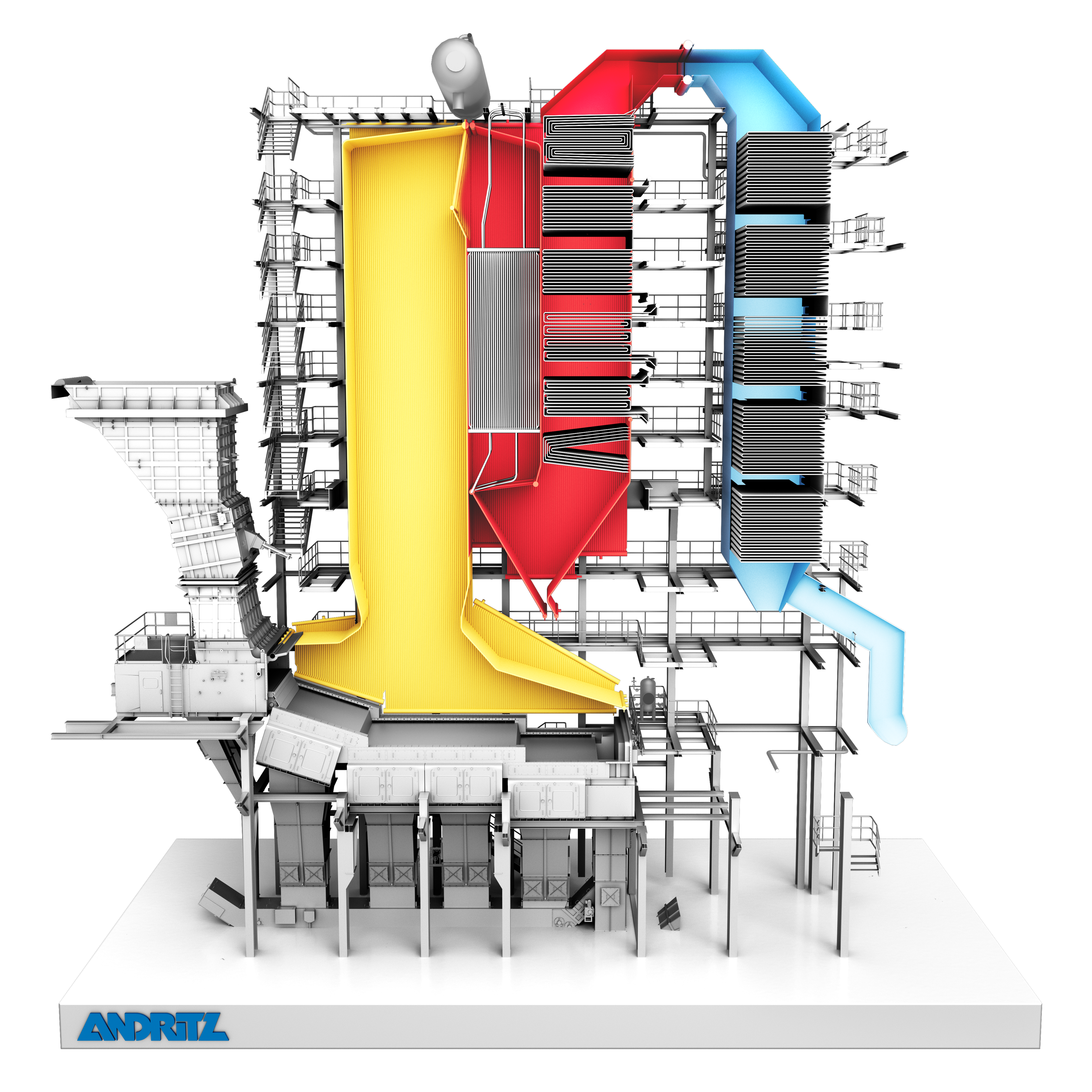

Designed with a solid metal construction, the combustion grate can be built horizontally or/and as inclined reciprocating grate. Our specialty is designing natural water/steam boiler circulation, which increases boiler operation availability and lifetime while decreasing maintenance. We base our design on calculations, experience, and engineering best practices.

The grate bars can be cooled with water-cooling circuit, air-cooling, water-cooling circuit and air-cooling combined, depending on the fuel's lower heating value. The thermal and mechanical stress of the grate bars is greatly reduced thanks to the right choice of media cooling circuit.

Choosing the right cooling media reduces thermal and mechanical stress on the grate bars, increasing boiler availability and reducing maintenance costs. For fuels with a high LHV - lower heating value, we use water to cool the grate bars, and the heat from the cooling water can be used to heat the combustion air. This returns heat to the boiler, increasing efficiency and reducing electric power and fuel consumption.

By heating the combustion air, we also have a positive effect on flue gas emissions. The primary air outlet openings are self-cleaning and can be adjusted according to the fuel.