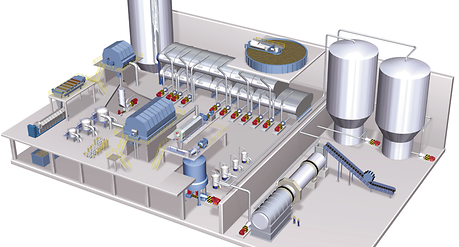

ANDRITZ deinking systems are based on experience and innovation

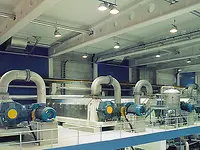

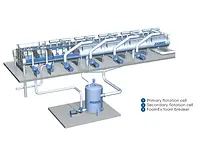

Global experience from many installations enables ANDRITZ to specify and build the right system for your deinking application. From pulping through screening, cleaning, flotation, thickening/dewatering, dispersing and bleaching, as well as sludge and reject treatment – every step is performed by highly efficient and reliable equipment. The entire process chain is designed to improve pulp and paper quality – enhancing your margins and reducing your production costs.