BrainWave dryer

The solution for stabilizing drying operations and improving moisture control

Control stabilization with BrainWave

ANDRITZ BrainWave is a patented advanced controller that outperforms traditional Proportional-Integral-Derivative (PID) control because of its two main components: an adaptive model and a predictive controller. BrainWave builds its own live models during normal plant operations, a powerful feature not offered by traditional Model Predictive Control (MPC) systems.

BrainWave’s predictive controller accurately forecasts process responses and accounts for multiple objectives. It adapts to process conditions, such as changes in production rate, keeping the process on target. BrainWave can also accept measured disturbance inputs, like raw materials properties, and takes corrective action before the process is pushed off target (PID, by comparison, must wait for the error to occur, and then react).

BrainWave easily integrates with existing control systems and its patented Laguerre technology means an average implementation time of just a few weeks. Best of all, the plant’s own staff can support and deploy BrainWave.

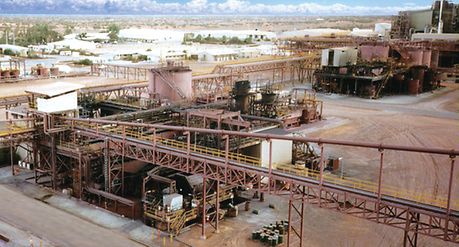

Drying plant at a mineral processing facility

Control stabilization for dryers

BrainWave stabilizes the operation of all types of dryers, resulting in improved moisture control of the final product and reduced energy consumption. The measured moisture content is stabilized at the dryer exit by continuous adjustment of the dryer temperature. BrainWave is ideally suited to control this application due to its ability to account for the long transport delay times as the product moves through the dryer to the moisture measurement sensor.

Further improvements to control are possible by monitoring incoming moisture content and including this in the control strategy as a measurable feed-forward. This allows BrainWave to make control corrections as soon as the incoming moisture changes, instead of waiting for the exiting moisture to respond. Variations in production rate cause the dryer dynamics to change dramatically. BrainWave is able to compensate for these changes by automatically switching controller configurations as production rate changes, further improving dryer efficiency.