ANDRITZ Oy

Finland

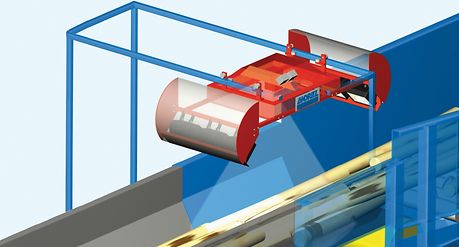

ANDRITZ WoodScan is an image processing system that continuously measures the quantity of bark on the logs exiting the debarking drum.

The system processes the data in real time, enabling the wood room operators or the control system to run the debarking process so that the cleanliness of the logs remains at an optimum level. WoodScan is typically utilized in connection with the debarking process optimization package.

Consistent cleanliness provides savings in raw material costs and also in pulp pre-treatment. Small reductions in the amount of raw material lost and/or chemical consumption can mean large annual savings. Furthermore, the end product quality improves because the logs are neither over- nor under-debarked.

The WoodScan sensor measures the debarking degree in real time.

The real time cleanliness degree data increases the visibility of the overall wood handling process, and provides the ability to analyze the debarkability of the logs under varying conditions.

WoodScan consists of a camera with lighting unit and a PC, including hardware and software. The camera records images of the logs on the conveyor. The frame grabber captures images from the camera and transmits them to the computer. The images are analyzed by special software that evaluates the amount of clean logs, bark, and background areas in the image. The processed data (such as cleanliness degree percentage) is transmitted to the main control system.