The key features of Cyclones include:

Efficient Particle Removal: Cyclones effectively remove larger particulate matter (PM), such as dust, ash, and coarse particles, from gas streams.

Low Operating Costs: Cyclones have no moving parts, which minimizes maintenance and operational costs. Once installed, they require little upkeep compared to more complex systems like electrostatic precipitators or baghouse filters.

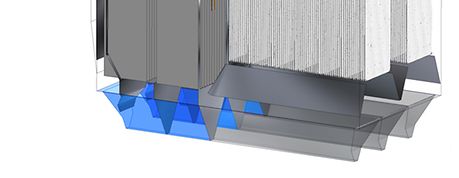

Simple Design and Construction: The straightforward design of our cyclones makes them easy to install, and integrate into industrial processes. This simplicity also contributes to their reliability and durability.

High-Temperature Tolerance: Our cyclones can operate effectively in high-temperature environments, making them suitable for industries like cement production, power generation, and metal processing, where hot exhaust gases are common.