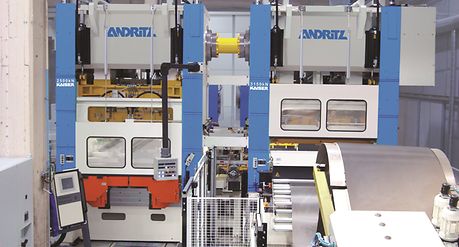

ANDRITZ Kaiser GmbH

Germany

Example of a twin-press-line with zig-zag feeder, coil handling line and automatic stacking system

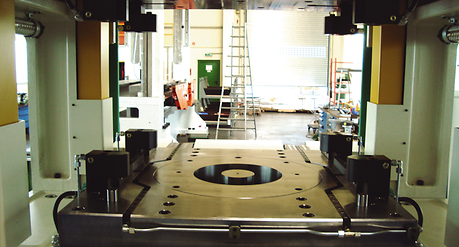

Precise timing and general performance are required for competitive productivity of high speed stamping systems for laminations. Due to the large amount of cutting operations required, a very rigid machine is needed to absorb the cutting impact without damaging any machine part. Finally, the tolerances of 0,02mm in the tools and the end product call for a very precise slide movement, slide guideance and low frame deformation.

Our well designed and thoroughly tested concept allows customers to manufacture high-quality products with maximum efficiency. ANDRITZ Kaiser production lines for electric motor laminations are characterized by the following features:

Every tool chamber is customer-specific

Fully automatic stacking system

With our motto “focus on performance” and our experience, ANDRITZ Kaiser delivers a great price-performance ratio. As a result of all the above benefits, our customers receive: