up to 1,250

m/min speed

Whether your technology is spunlaid, drylaid, airlaid, or wetlaid, ANDRITZ Nonwoven provides the perfect nonwoven calender to suit your special needs and final product demands.

Benefit from our unlimited portfolio and our broad know-how for thermobonding, embossing, perforation, compacting, and lamination. Depending on your final product and its parameters, like strength, softness, or air permeability, our nonwoven calender portfolio ranges from low and medium capacities (aXcess range) to high capacities (eXcelle range), precisely designed to meet your needs.

m/min speed

calenders installed

mm width

N/mm line force

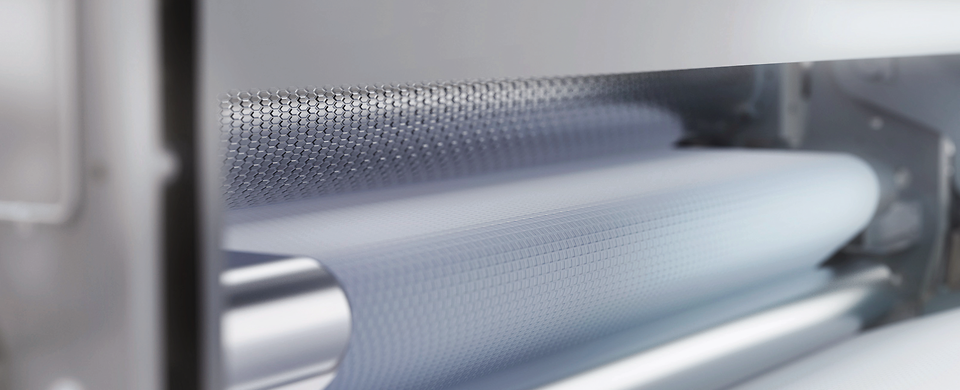

Hot S-Roll – the heart of our nonwovens calendering technology

Nonwovens compacting and calibrating process

| neXcal compact | two-roll compact calender | initial demand and lower speeds |

| neXcal twin aXcess | three-roll compact calender | top flexibility in medium-capacity |

| neXcal | two-roll calender | high-capacity spunbond production |

| neXcal twin | three-roll calender | top flexibility in high-capacity |

| neXcal twin pro | three-roll calender | ultimate flexibility in high-capacity |

| neXcal sizer | two-roll calender incl. CS-Roll | airlaid processes |

| neXcal embossing | two-roll or three-roll calender | embossing of spunlace nonwovens |

| neXcal laminating | two-roll calender | lamination of at least two layers |

| neXcal ultrasonic | ultrasonic vibration calender | Bonding and laminating with ultrasonic vibrations as thermo-mechanical process |

Nonwovens calendering

Drawing on our S-Roll core competence, all rolls and key components are manufactured and mechanically tested at our facility in Krefeld, Germany. Roll technology efficiency is crucial to the success of the final product. All our neXcal nonwoven calenders are equipped with a deflection-controlled Hot S-Roll with a surface temperature up to 275° C.

Cooperation with the best roll engravers ensures consistent quality during the nonwovens product development stage plus the largest selection of patterns available. In addition, an own technical center offers the possibility of comprehensive trials at laboratory scale as well as practical expert advice.

With more than 600 nonwoven calenders in operation worldwide, installations in all high-end spunbond nonwovens lines, and more than 750 innovations with patents granted or pending, ANDRITZ Küsters stands for top performance, reliability, flexibility, and proven nonwoven calender technologies.