DDS bottom screens

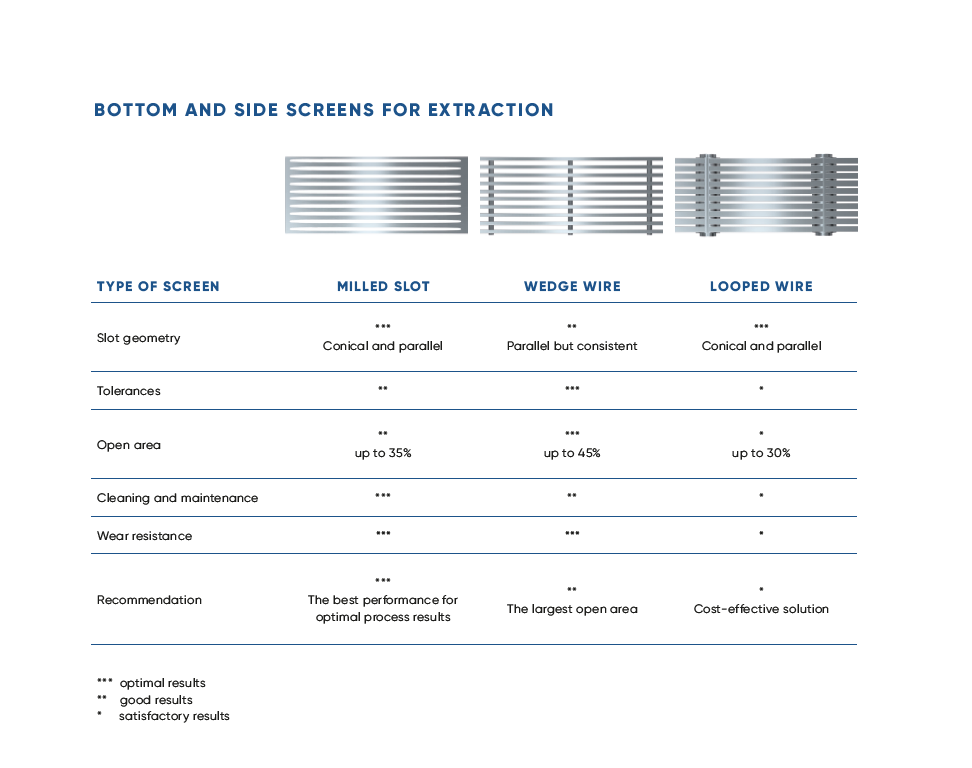

DDS screen trays are used during extraction. They are used to retain the pulp. We can offer you DDS screens in punched, drilled and slot-milled versions. The retention of the pulp and additionally the capacity can be increased by the choice of perforation.

Benefits:

- High stability and durability due to high material thickness

- Improved dewatering performance

- Process optimisation by changing the screen opening possible

- Available drilled, milled or punched