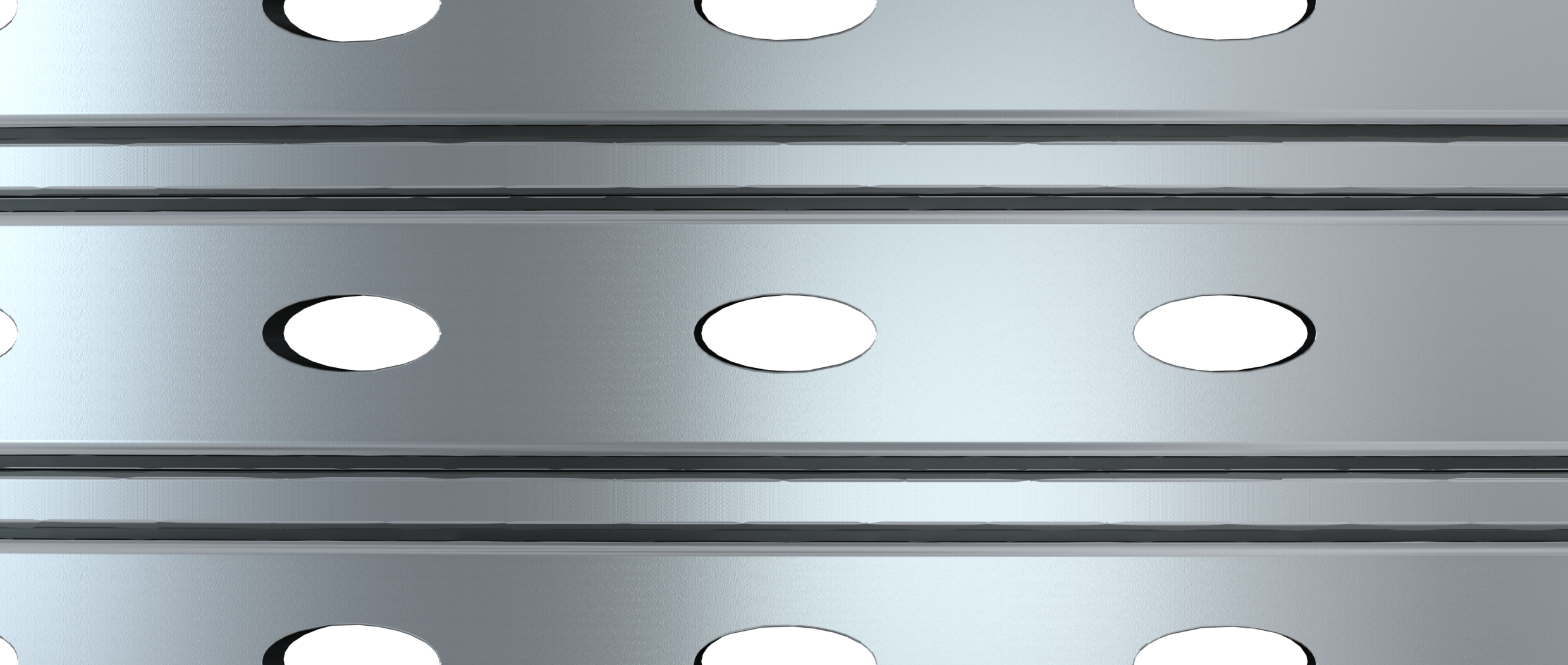

Maximum Yield centrifuge basket

Our high-tech screen basket for discontinuous centrifuges with maximum yield technology consists of three individual baskets:

- A fine screen made of wedge wire with a multiple life compared to the previous standard screen, with a significantly higher open area for a faster and more efficient separation of sugar crystals from the mother liquor

- A support basket also made of wedge wire, which reinforces the fine screen and does not reduce the open area of the fine screen

- A screen drum made from a modern duplex material. This patented and TÜV-approved new design is characterised by its long service intervals, high operational reliability and reduced cycle times. This novel design with elliptical openings and V-ring construction reduces the stress peaks in the process from over 500 MPa to 275 MPa.

Benefits:

- Maximum open area for highest dewatering performance

- Reinforcement rings for maximum stability and safety

- Reduction of cycle time by up to 50%

- Significant reduction of residual moisture (up to 50%)

- Increase the sugar yield (up to 6%)