Optimization, data analysis, augmented reality

Customized high-consistency refiner plate solutions for every mill

ANDRITZ HC refiner plate specialists work with your team to develop cost-efficient solutions. We offer a range of high-performance refiner plates to optimize production costs and pulp quality.

ANDRITZ delivers customized solutions in the form of high-consistency refiner plates for mechanical pulp producers, dispersion processes, and chemical pulp refining. State-of-the-art technology allows for energy savings and pulp quality enhancement.

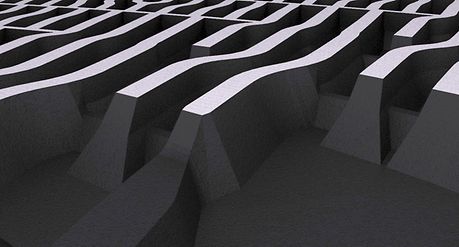

FiberMaxX refiner plates are used for softwood chip refining to maximize fiber length and strength properties in the pulp

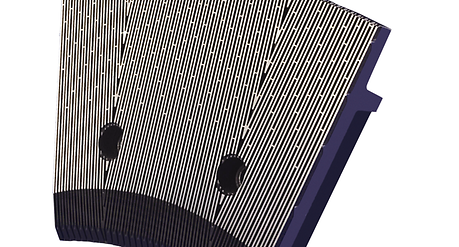

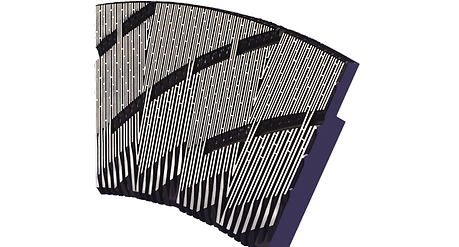

Steam pockets and triple-pitch construction are used in DuraMaxX refiner plates to improve loadability and stability of refiners

CR plates feature a feed injector inlet for efficient feed, together with a fine VP pattern in holdback for low-intensity refining

Our specialists have taken refiner plate design, development, and application to the forefront of technology. With increased focus on performance improvement, ANDRITZ has taken significant leaps forward in refiner plate technology, developing such refiner plate concepts as:

- Directional plates

- Variable pitch

- Feed injector

- Chip doctor

- Steam pockets

- FiberMaxX

- DuraMaxX

- SEnergy

- Chip compressor

- as well as our most recent energy-saving technology: LE-Gator

ANDRITZ understands that refiner plates are only one part of the refining solution. The right application and overall refining strategy are just as important. Our experts study your process and your requirements (in terms of pulp quality, production bottlenecks, etc.) in order to evaluate the best possible complete solution – which includes advanced refiner plate designs customized to your requirements.

Energy savings area key demand in the industry

The optimization of energy usage has to be a top priority in mechanical pulp production. Yet, no compromise can be made in pulp strength properties and pulp quality.

The FiberMaxX family of refiner plates produces the strongest mechanical pulps on the market, while minimizing energy demand to achieve this.

SEnergy plates are mostly used for the lowest energy input target, where pulp strength properties are not the major requirement.

Chip doctor and chip compressor products allow for pre-treatment of wood chips to enhance pulp properties.

Our latest LE-Gator design enables significant energy savings, while preserving valuable strength properties in pulp.

TMP, RTS, PRC-APMP, BCTMP, and many other applications have been proven in all mechanical pulp processes.

Other applications of HC refiner plates

HC refiner plates are also used in chemical pulp plants for blowline, deshive, and sack kraft refining. For example, triple-pitch and CR-plates have proven to be of very high value for sack kraft refining, where high TEA can be developed with less energy compared to conventional plates.

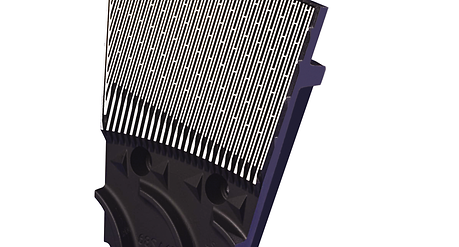

Durapulse – disperser plates

For disperser plates, ANDRITZ took the simple concept of intermeshing teeth to new heights of technology. Our Durapulse double-edge tooth has become an industry standard. V-tooth and X-tooth designs have improved plate life in most applications, while the use of varying tooth angles can further optimize energy and dispersing efficiency.

Alloys

ANDRITZ continuously evaluates new alloys for refining applications in order to obtain the best wear properties while maintaining high strength and ductility to suit HC refining applications.

This product range is available for flat and conical refiner segments. Our experts are ready to help you reach your improvement targets.