Optimization, data analysis, augmented reality

TecnoWeave Dynapulp fabrics

Triple-layer dewatering belts for Fourdriniers and Twin Wire Formers

TecnoWeave Dynapulp fabrics are applied for dewatering of pulp on Fourdrinier machines and Twin Wire Formers.

Heat-treatment of Dynapulp fabrics

The optimized triple-layer structure of Dynapulp is specifically designed to meet the demanding requirements of pulp dewatering. Dynapulp provides high dewatering capacity as well as good retention of fibers. Even though it is a relatively thin fabric, it has an extended lifetime due to the high wear volume created by the weave design.

The thin fabric design minimizes water carryover and the fine upper side reduces fiber loss due to its high mesh, while the robust under side contributes to its long lifetime.

Dynapulp fabrics are produced with woven seams or pin seams.

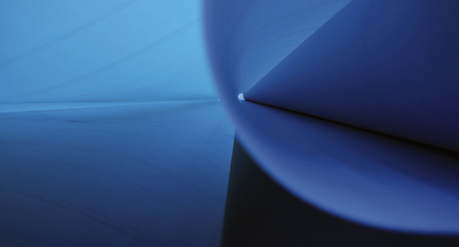

Illustration of Dynapulp dewatering belt

Dynapulp advantages:

- High dewatering capacity

- Good fiber support on the paper side

- Good retention of short fibers

- Best fiber retention, smooth sheet, less debris and dust in the drying section

- Long life

- Dimensional stability

- Less carry-over of water and air

- High efficiency in vacuum boxes

- High efficiency in the drying section

- Tested in pilot facility and in practice