CHAIN MONITORING

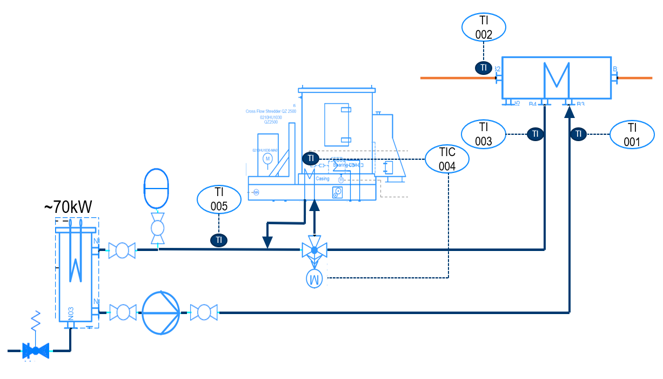

Our Chain Monitoring System is a cutting-edge solution designed to enhance the efficiency and reliability of your operations. Here's how it works:

Idea of the system

Our system is equipped to detect one-sided chain breakage and promptly issue warnings on the human-machine interface (HMI). Additionally, it generates automatic lists to assess the statistical distribution of fridges per chain. This proactive approach ensures that potential issues are identified and addressed before they escalate, thus minimizing downtime and maximizing productivity.

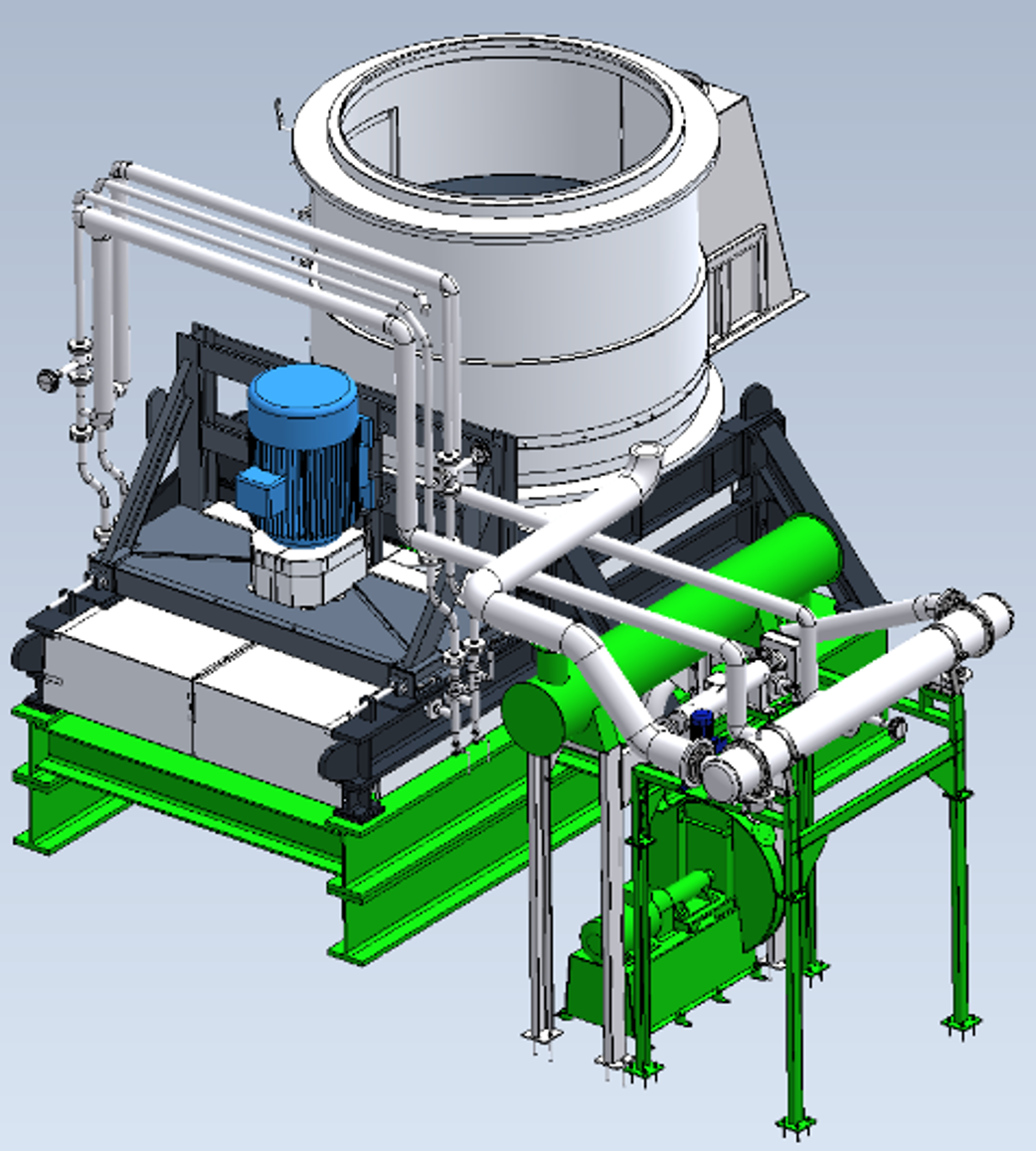

Understanding chain wear

The wear that naturally occurs in chains can lead to the critical point of the chain—the last chain link—breaking off. This loss not only affects output, but also compromises the quality of the entire downstream process. Our system detects these issues early, allowing for timely interventions to maintain optimal performance.