ANDRITZ AG, Austria

regeneration systems for carbon steel

Eibesbrunnergasse 20

1120 Vienna

The waste acid generated can either be discharged – which results in high costs and high fresh acid demand – or regenerated. The ANDRITZ HCl regeneration technology includes systems for hydrochloric acid, which is used either in carbon steel pickling or for the production of metal oxides.

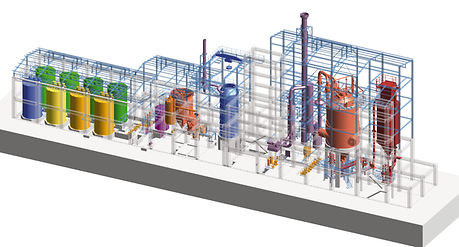

Regeneration plant

Waste acid is thermally decomposed in a reactor with direct firing. This reactor can be either a spray roaster or fluid bed type. Rinse water from the pickling line is used for absorption of the hydrogen chloride, thus producing regenerated acid with a concentration of up to 18% HCl. Off-gas cleaning is imperative in order to meet the most stringent emission standards. If the specially designed WAPUR process is also used, high-quality oxide is obtained as a by-product.

Acid recovery is an important part of the overall pickling process, in both economic and environmental terms. Nowadays, practically all the acid used in pickling is recovered, thus consumption of fresh acid is extremely low. The choice of either a spray roasting or a fluid bed process for this purpose depends on the situation at the customer’s plant.

Spray roasting generates a by-product of powdery red iron oxide, which can be used for many applications, especially in ferrite magnets and pigments. The WAPUR process developed by ANDRITZ can improve many impurities from the pickle liquor, and the resulting oxide has a higher value than the standard grades.

The by-product of the fluid bed process is a heavy, gray granular oxide, which can be recycled to the iron-making process or used for applications such as counterweights and the like.

Our plants are operated using state-of-the art PLC and control systems as well as our highly developed software. Furthermore, all operation and simulation modes are covered, paired with highest availability and safety for your personnel and for the plant.

Advanced 3D design and modelling tools

Reactor base