Features of Intelligent Plant Floor Management

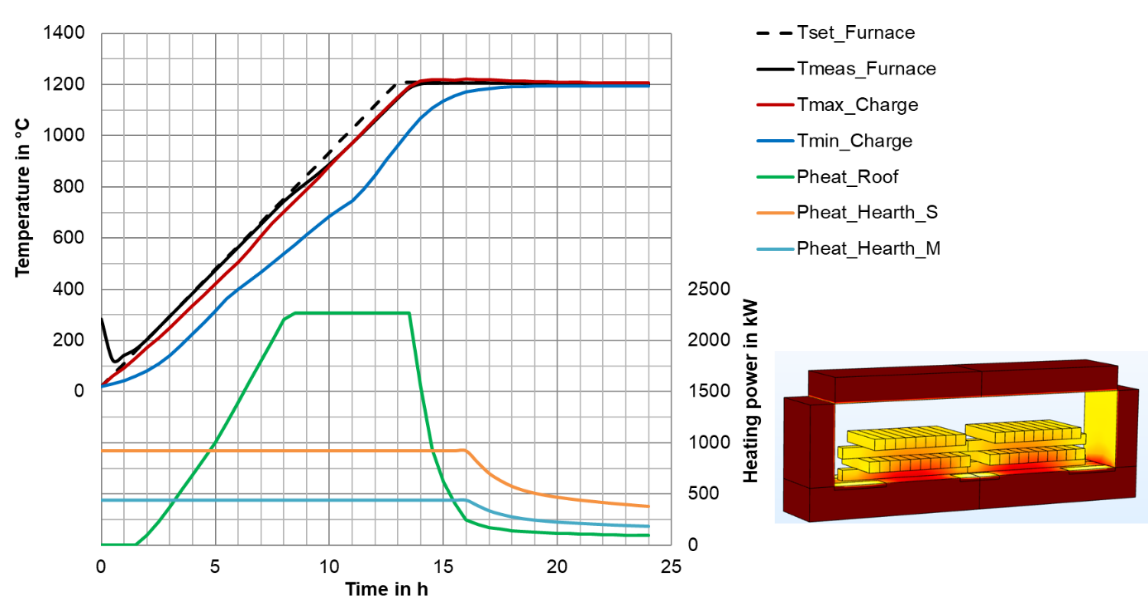

- Heat treatment models

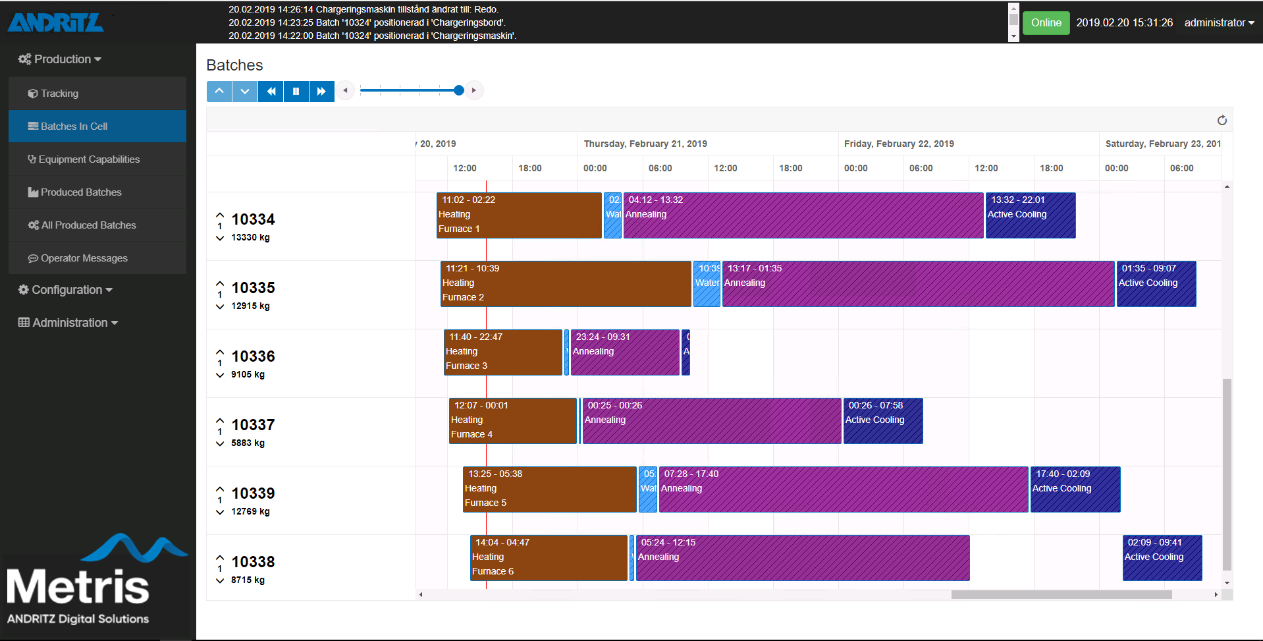

- Intelligent scheduling

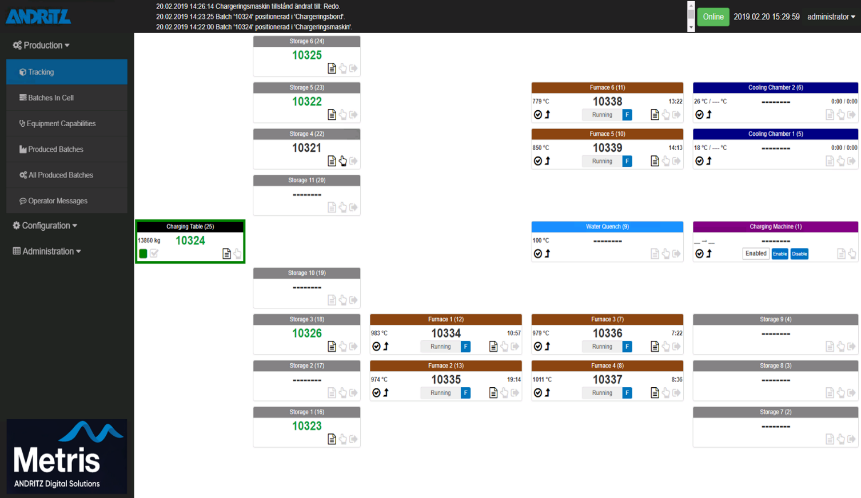

- Automated plants operation

- Dynamic work orders

- Track & Trace (OEE, KPI, WIP, Inventory…)

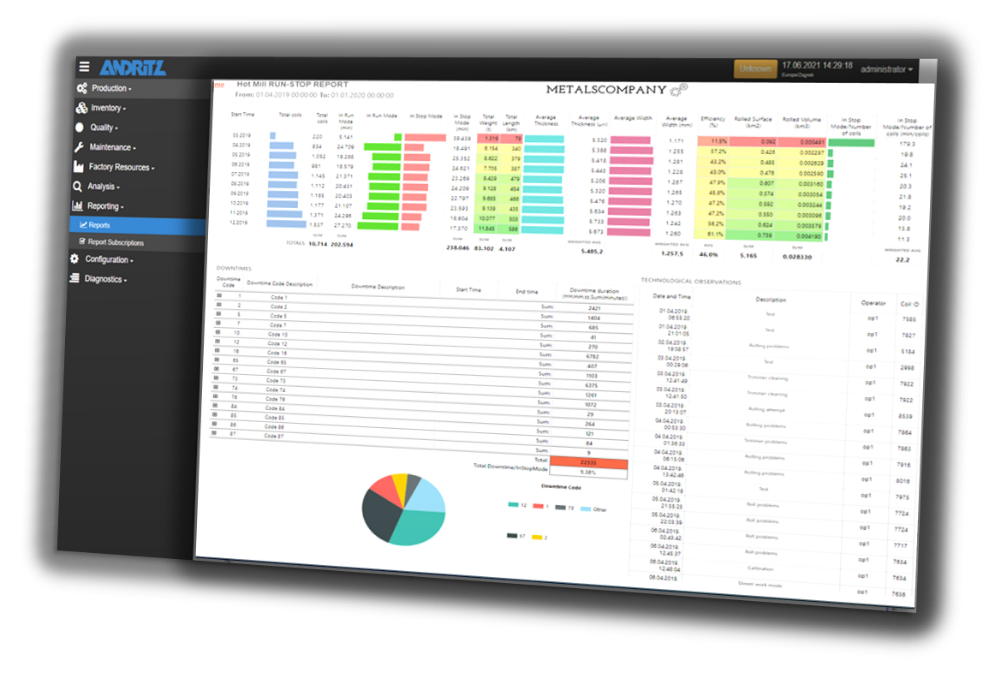

- Quality Assurance (reporting)

- Reporting in real-time and on demand (quality, production, performance, maintenance, energy, CO2 footprint…)

- Analysis (historical data on production, quality, performance…)

- Mobile solutions (Tablets, Smart Phones, remote access…)