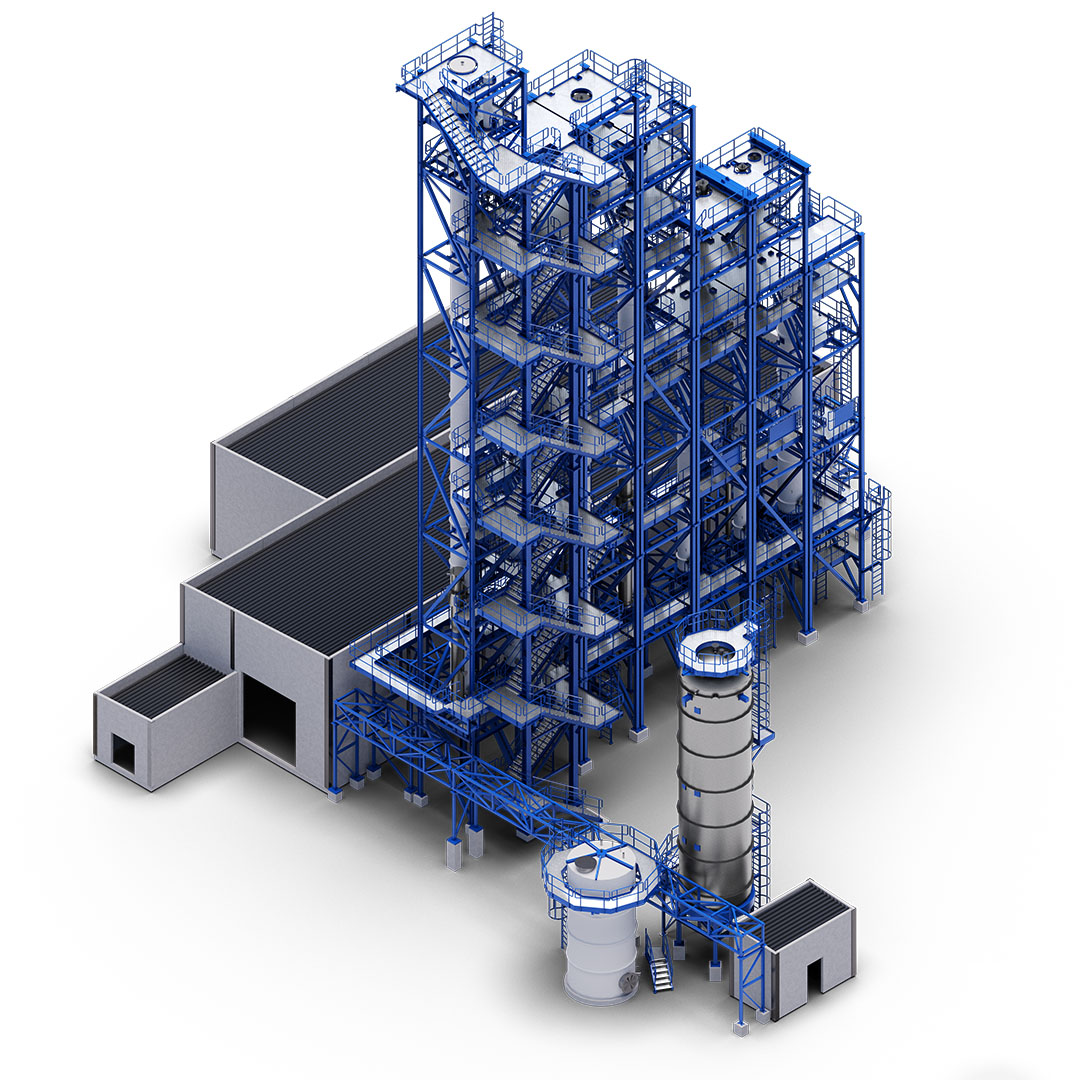

The plant utilizes WSA (Wet Gas Sulfuric Acid) technology developed by Danish company Topsoe. While relatively new in the pulp industry, the technology is well-proven, having already been licensed to operate at nearly 200 locations worldwide, in many industrial sectors. ANDRITZ has already successfully introduced SulfoLoop systems into the pulp industry with installations at two mills in Brazil, Klabin Puma and Suzano Ribas do Rio Pardo with another plant under construction in Sweden Södra Cell Mönsterås.

The Topsoe WSA process is a wet gas catalytic process. The concentrated sulfuric acid is produced by condensation from a wet process gas. Drying of the process gas prior to treatment in a Topsoe WSA plant is completely unnecessary, which means generation of wastewater and loss of sulfur are avoided.

The purpose of the first step in the process is to produce an SO2-rich gas at the operating temperature of the oxidation catalyst in the SO2 converter. Sulfurous feeds are oxidized to SO2 by combustion and then cooled to the optimum catalytic conversion temperature in a waste heat boiler. The excess heat from this operation is recovered as steam.

The catalytic conversion of SO2 to SO3 takes place in one or more catalyst beds. The reaction heat is recovered between the catalyst beds by production of saturated or superheated steam. After the last conversion step, the gas is cooled and the SO3 reacts with water vapor to form gas-phase sulfuric acid. The process gas is finally cooled by a countercurrent flow of air in Topsoe’s proprietary WSA condenser.

Clean tail gas exits at the top of the WSA condenser and the sulfuric acid is collected in the bottom section from where it is cooled and sent to storage. Hot air generated in the WSA condenser may be used to preheat combustion air of the recovery boiler, to ensure optimal energy efficiency.