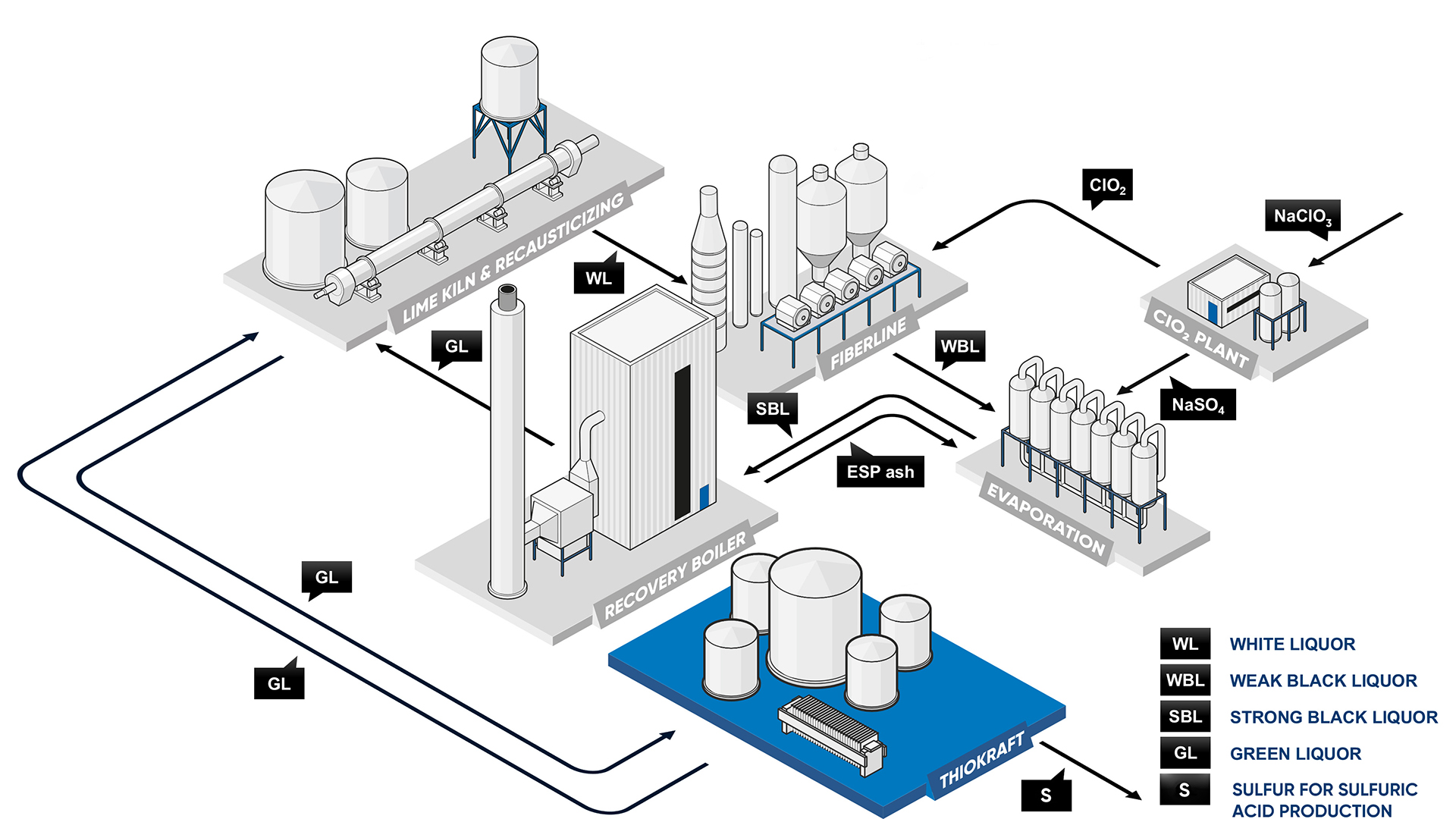

How ThioKraft technology works

Controlling the sodium sulfur balance at a pulp mill is a crucial task and can be expensive when it comes to purging sulfate streams and adding make-up chemicals to achieve the perfect result. So, imagine being able to control the required sodium sulfur balance in the process, and at the same time producing a usable side stream of sulfur.

The ThioKraft process is designed to benefit the control of the sodium sulfur balance by extracting only a minor share of the green liquor and removing the sulfur using bacteria in a bioreactor. Bacteria originating from soda lakes are able to withstand high salinity and pH. The green liquor is then treated in a bioreactor where the bacteria oxidize sulfide-ions into elemental sulfur, finally producing sulfur cakes.