SYNERGIES WITH THE SulfoLoop SULFURIC ACID PLANT

ThioKraft can run alongside ANDRITZ’s SulfoLoop sulfuric acid plant. The sulfuric acid plant only removes some 4 kg of sulfur per ADT of pulp from concentrated non condensable gases (CNCG) without additional process steps. For the sulfur recovery plant, there is no technical limit for the sulfur extraction, which can be very useful, for example, in mills investing in lignin recovery.

Sulfur recovery plants are economically viable even at small pulp mills, unlike sulfuric acid plants, which need larger scale. Ideally, multiple nearby mills would host sulfur recovery units feeding one central sulfuric acid plant. Alternatively, adding sulfur recovery enhances flexibility in mills expanding capacity or investing in processes like lignin recovery.

Pesola explains, “With ThioKraft, as long as the sulfuric acid plant is designed to run complementary with elemental sulfur, the mill can, in future scenarios, take more sulfur out of the cycle and replace part of the purchased elemental sulfur with internally produced sulfur.”

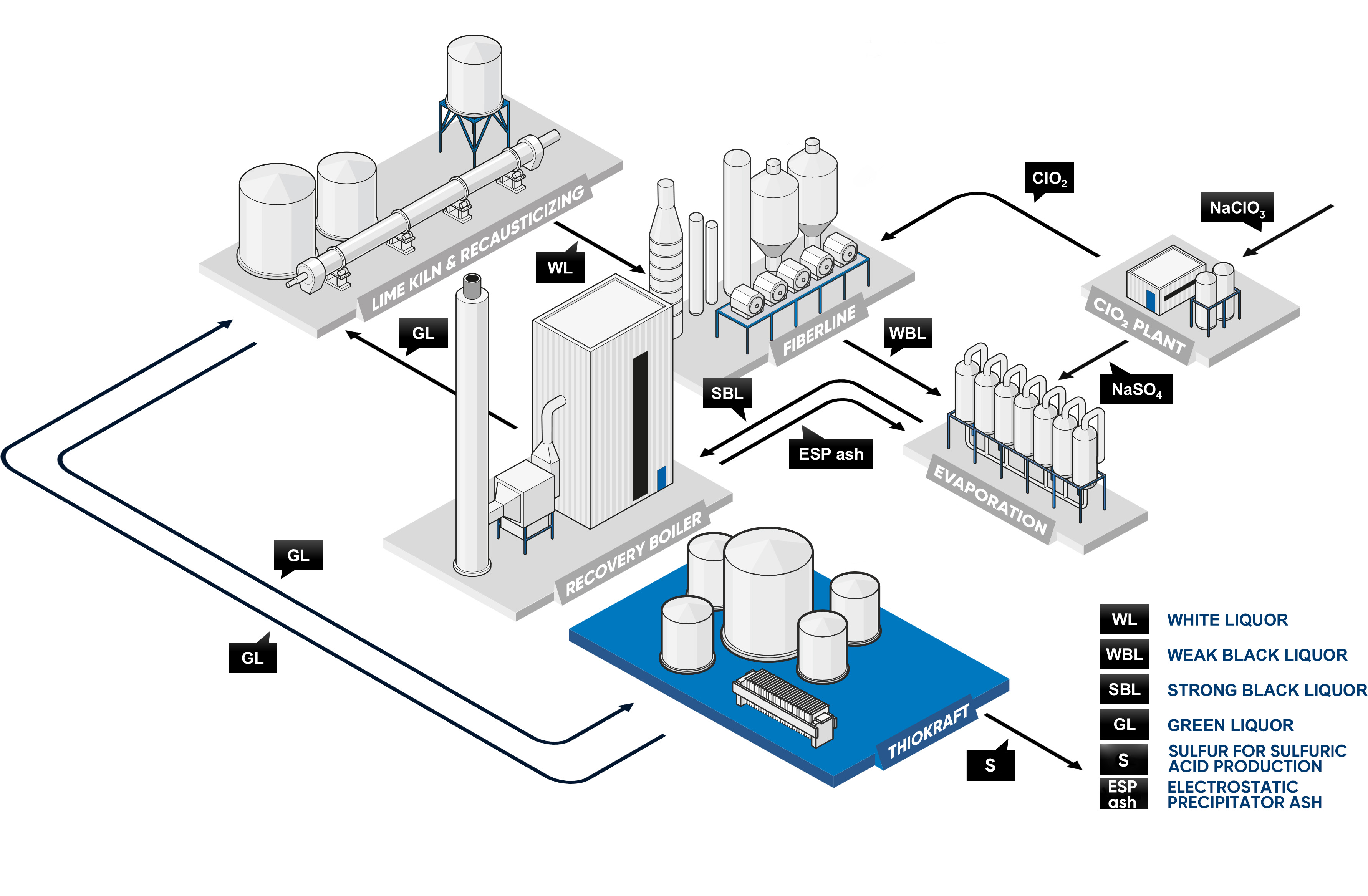

The ThioKraft system utilizes not just green liquor from the mill, but also CO₂ from the flue gases. In addition, the system can use mill internal liquid streams instead of fresh mill water. “Obtaining CO₂ from the lime kiln is another advantage of the ThioKraft system as it closes more loops and avoids the cost of acquiring CO₂ elsewhere,” adds Pesola.