Mr. Shi Wei adds, “Through localized production at our Foshan facility, ANDRITZ has achieved full in-country integration across the entire value chain - from design and manufacturing to service. This allows us to help customers cut initial investment costs by up to 30%, which is a clear example of how we deliver on our promise of ‘Growth that Matters’.”

Building Operational Resilience Through Full Lifecycle Services

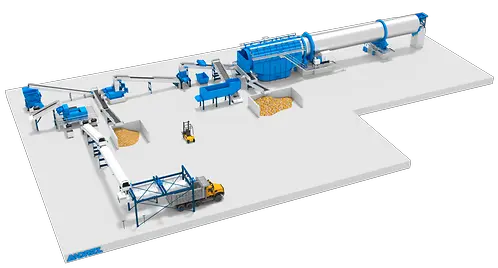

ANDRITZ’s competitive advantage lies not only in its technology but also in its comprehensive lifecycle services. “We regard the dry reject treatment system as an integral part of the entire pulp and paper production ecosystem,” explains Mr. Zhu Zhipeng. “Leveraging ANDRITZ’s global leadership and expertise across pulp, paper, and energy, we deliver fully integrated solutions covering the entire value chain - from pulping and papermaking to energy recovery and waste treatment. This closed-loop approach significantly boosts operational efficiency and resource utilization.”

ANDRITZ’s full lifecycle service philosophy also delivers clear benefits in maintenance and reliability. “By implementing standardized preventive maintenance programs, we greatly reduce unplanned downtime and help customers lower overall operating costs,” Mr. Zhu adds. “Beyond comprehensive start-up training and complete spare parts support, we tailor maintenance strategies based on real-time equipment performance data. For example, when a customer reported accelerated wear due to high sand content in the feedstock, our technical team quickly designed a new sealing assembly and executed a retrofit, effectively resolving the issue in record time.”