Maintenance, upgrades, optimization, spare parts, wear parts

Optimizing wood chip quality: Big savings and a leap in pulp production

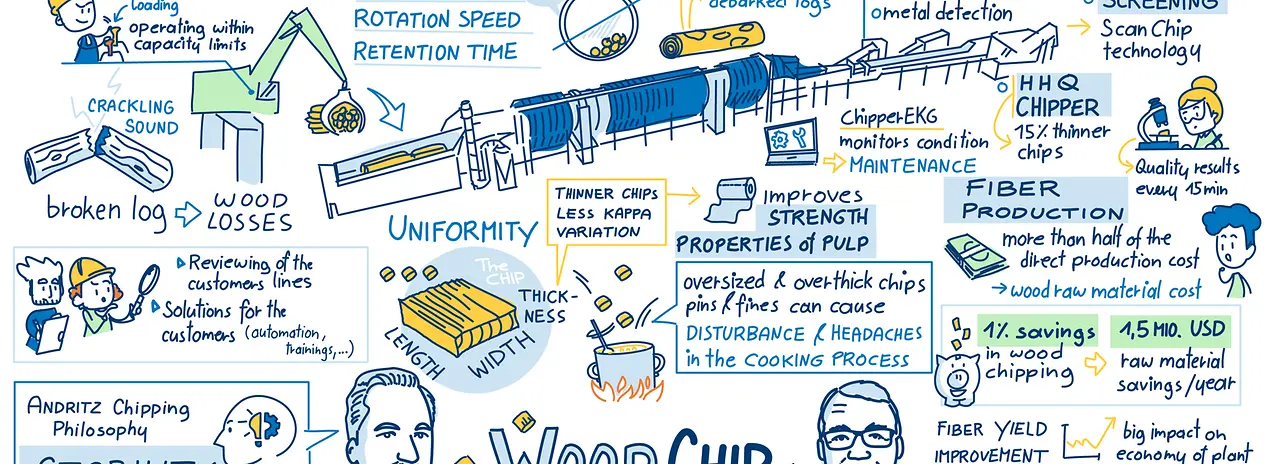

ANDRITZ’s deep knowledge of woodyard operations combined with its state-of-the-art processing technology enables pulp producers to achieve remarkable financial results when it comes to reducing wood loss, improving chip quality, and optimizing fiberline performance.

Are you aware of the major savings that can be made at a high-capacity pulp mill by simply improving and optimizing the quality of the wood chips going into the fiberline? The numbers are really quite surprising.

“A saving of $ 1.5 million per year is highly achievable by ensuring the minimum of wood losses in the woodyard,” explains Harri Soila, Senior Vice President, Wood Processing Services, ANDRITZ. “And even more gains can be made in the fiberline by producing good quality, uniform chips.”

Hannu Silventoinen, Wood Processing, Go to Market Management, ANDRITZ adds, “Improving the yield of the wood from the chipping line, as well as providing good quality, homogenous chips, will enable an increase of up to 12,000 t/y of pulp production at a large mill, which we conservatively estimate to be an increase of $ 3 million per year in extra revenue.”

Debarking & Chipping line

STABILITY IS KEY, WITH A GENTLE TOUCH

So how are these significant, minimized wood losses achieved? The impressive results are obtained by utilizing ANDRITZ’s chipping philosophy, a straightforward approach to always deliver bespoke, customized solutions to meet individual mills’ capacity and process needs. Soila explains, “Whatever the process at the mill, batch digester, continuous digester, or even a refining process, the key word is 'stability'. We want to ensure the best quality chip with the minimum wood losses across the woodyard processes.”

Using its chipping philosophy, ANDRITZ looks holistically at ways to improve and stabilize woodyard operations across the whole process, from log management, to the debarking drum, chipper line, and the chipper itself followed by the screening process, oversize treatment, and bark processing and storage.

“Throughout each of these processes we can always find opportunities to prevent wood losses,” says Soila. “For example, if you hear a crackling sound in your woodyard, it means you are handling your logs in an abrasive way, and a broken log will lead to wood loss. This means it is key for loaders to operate within the capacity limits as gently as possible causing minimum damage.

“When it comes to the debarking process, again, the key word is always stability and it is important that the mills operate at the right filling degree and rotation speed along with having the right retention times. This is critical for wood cleanliness, the main KPI in the debarking drum.”

The same attention is also paid to the drum and chipper line where it is important to have effective bark separation, good washing, and stone and metal detection. “All of these factors are critical to maintain constant infeed to the chipper,” says Soila. “Constant feed is essential, and the more stable the process the better the chip quality will be. All this also comes with reducing wood losses across the whole process.”

UPM Paso de los Toros, Uruguay

PREMIUM CHIP QUALITY – PREMIUM RESULTS

To produce top quality pulp consistently, premium wood chip quality is essential. When it comes to the fiberline, uniform, homogenous chips with no pins and fines make for a much more stable process.

Silventoinen says, “More than half of the direct production costs at a chemical pulp mill come from the cost of wood. This means every increment saved in wood losses in the woodyard equals extra yield in the fiberline. However, even more important to the process is to improve the yield in the fiberline by having good quality chips.

“In general, variations in all aspects of chips will cause a mill headaches in the fiberline. If the chip size varies, controlling the cooking is difficult, especially if the chip thickness varies. ANDRITZ mill operation experience has shown that after introducing its latest modern chipping equipment and chipping philosophy, the stability of the cooking process is enhanced. This improves overall fiberline performance and allows increased fiber yield.

Silventoinen adds, “At the same time as improving the yield, fiber properties like strength are improved, bringing important gains when it comes to pulp quality.”

ANDRITZ CHIPPING PHILOSOPHY – A COMPLETE SOLUTION

ANDRITZ provides a complete solution from debarking to chipping with the ultimate aim of producing high quality chips for the fiberline with minimum wood loss. Under its PartnerChip concept, which involves service of the chipper as well as tailor-made services for the rest of the woodyard, ANDRITZ can assure customers that their woodyard operations are fully optimized and create growth that really matters to a pulp mill.

As well as offering the PartnerChip service, ANDRITZ also provides state-of-the-art technology, including its HHQ Chipper, which has proven to be the most popular chipper on the market since its launch in 2001. ANDRITZ also supplies the latest in smart technology for the woodyard, including the ScanChip analyzer that measures the size and dimensions of the chips in real time, and the Chipper EKG that monitors the condition of the knives, all of which ensure optimum uptime.

If the moisture content or density of the chip varies, the cooking parameters need to be adjusted accordingly. Also, if there are pins or fines, they normally over-cook, consume chemicals, and reduce the chemical cycle of the mill.

ANDRITZ HHQ Chipper