“We are trying to do things that nobody else can do. Not just the mainstream stuff.”

Maria Nordgren

CTMP Line Manager, SCA Ortviken

In today’s digital age, it is no secret that demand for graphic paper is falling in most parts of the world. One company that reacted decisively to this reality was SCA, which radically changed the business model of its Ortviken mill, on Sweden’s east coast. The mill pivoted from graphic paper to supply the growing packaging and hygiene paper industries with market pulp, setting itself up for a more sustainable future.

SCA’s CTMP needs to have dramatically different physical characteristics to be suitable for the different end-use markets, with at least 25 customized recipes.

This strategic turnaround involved SCA closing the publication paper machines at Ortviken, and converting the associated thermomechanical pulp (TMP) plant to make SCA More, the firm’s range of chemi-thermomechanical pulp (CTMP). The project tripled Ortviken’s pulp capacity to almost 300,000 tons/year, and was completed in 2023.

Maria Nordgren

CTMP Line Manager, SCA Ortviken

A key factor here is that SCA More involves a very wide spectrum of CTMP qualities. It includes at least 25 spruce and birch recipes and is, according to Mill Manager, Anders Granström, “an impressively broad product portfolio.”

For tissue mills, the shorter-fiber birch variants with high fiber freeness provide both absorbency and softness, while the lower- and mid-freeness pulp grades are well-trusted by packaging producers. Other end uses for the mill’s CTMP include molded fiber-based trays in the food industry and growing substrate, e.g., for growing herbs. Maria Nordgren, CTMP Line Manager at Ortviken adds, "With our experience, we will be able to use our new state-of-the-art operation and R&D resources to develop even more new products.”

ANDRITZ upgraded SCA’s disc filter in a way to handle a very wide range of fiber freeness profiles.

Converting Ortviken to make such a wide range of pulps presented a fascinating technical challenge. Because the mill’s CTMP needs to have dramatically different physical characteristics to be suitable for the different end-use markets, its fiber freeness can vary from 300 to 750 CSF (Canadian Standard Freeness). Normally, a pulp mill would use two separate disc filters in the dewatering stage to handle such a wide range of fiber freeness profiles. But SCA had other ideas.

Rickard Persson

Process Engineer, SCA Ortviken

Ortviken asked several firms to propose a solution that would meet all of these needs, using just a single disc filter. An extremely ambitious goal, but as Ortviken’s Process Engineer, Rickard Persson, explains, “we are experienced, we know what is possible. But we are also engineers – we are curious to push, to explore and learn new things.” Maria Nordgren agrees, “We are trying to do things that nobody else can do. Not just the mainstream stuff.” The other invited suppliers chose not to go on this journey, but ANDRITZ did. As Rickard Persson concludes, “we put the idea on the table, and ANDRITZ accepted the challenge”.

Daniel Stelzer

Product Manager Disc Filter Service, ANDRITZ

Erik Nilsson, Paper Service Manager Scandinavia, ANDRITZ, says, “we were honest about the possibilities. We didn’t promise anything we weren’t confident of delivering. The trials went well, we were quick to answer their questions, and they got a good feeling.” Daniel Stelzer, Product Manager, ANDRITZ, agrees, “we offered a good technical solution, and with our existing relationship, they trusted us.” Ortviken’s Maintenance Manager and CTMP conversion project manager, Anders Mattsson, explains, “there was unknown territory when it came to the extremes of fiber freeness, but we were willing to take the risk, because ANDRITZ was willing, too.” Daniel Stelzer confirms, “it was clear from the beginning that this project was extremely challenging, but SCA was willing to work with us. We didn’t try to change their expectations - rather, we focused on our solutions and committed to solving any problems that might come up.” Erik Nilsson adds, “we keep our promises, we don’t run away.”

Erik Nilsson

Paper Service Manager Scandinavia, ANDRITZ

As 300 and 750 CSF are such starkly contrasting extremes, which had never been achieved on a single machine before, Daniel Stelzer says, “it was like asking us to design a truck that could win a Formula 1 race!” To make it possible, the solution ANDRITZ came up with included newly-developed technology, which didn’t exist before this project: “These parts were developed entirely from scratch and represent completely new designs, with no prior comparable references. It ended up being almost a completely new machine,” he explains. “The only part left of the old disc filter was the legs!”

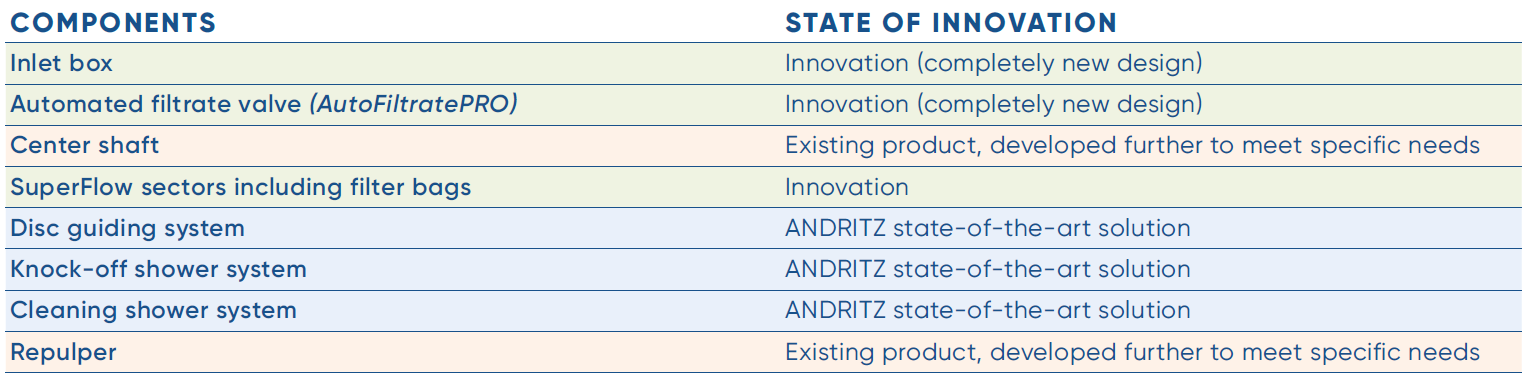

New developments included re-designed inlet boxes, 22 filter discs (with 396 sectors) instead of 15, completely-new designs for the filter bags, and a new automated filtrate valve that ANDRITZ is now marketing as the ‘AutoFiltratePRO’. The redesigned center shaft also set a new ANDRITZ record for filtrate volume (130,000 l/min), and there were further innovations on the repulper. To complete the package, the ‘standard’ parts are all ANDRITZ’s latest state-of-the-art equipment (see table for full details).

So it is safe to say that there is no other disc filter like this in the world. “It’s difficult to explain that one machine can now do the work that used to require two,” says Erik Nilsson. “This is a unique achievement. You won’t find another one anywhere else in the world. There is nothing even close.”

The disc filter upgrade featured both entirely new components and our advanced, state-of-the-art solutions

ANDRITZ supervised and helped with the removal of the old machinery, the installation and startup of the new equipment. To ensure the agreed guarantees were achieved, ANDRITZ made some modifications at both ends of the CSF range during the disc filter’s startup phase, in close cooperation with Ortviken. And the modifications worked. As Daniel Stelzer states, “we guaranteed production volume targets for different pulp freeness levels, and we met them all.”

Erik Nilsson says, “it was installed on time, started up on time, and after we made the necessary adjustments, it’s running extremely well – almost too well, as Ortviken doesn’t need us to do any service work! There are no issues, no hiccups, no-one calling us with problems.” Rickard Persson confirms, the new disc filter “is functioning really well. We are still making small alterations and improvements, both on our own and together with ANDRITZ.”

There have been a few requests for similar projects from other mills, and ANDRITZ is working on those, too. But despite being the only company in the world to offer a disc filter with such wide capabilities, ANDRITZ doesn’t expect to sell very many of them. As Daniel Stelzer points out, “there aren’t too many mills that would need such flexibility in a single unit.”

Anders Mattsson

CTMP Conversion Project Manager, SCA Ortviken

One is to show that ANDRITZ is not just selling off-the-shelf products but is willing to work with a mill to meet special requirements and solve unusual problems. As Erik Nilsson illustrates, “what we achieved here was really difficult, close to impossible. It was an unbelievable project in such a short time. It took many, many hours of engineering, day and night, but it was enjoyable. Like our former company motto says: We accept the challenge.”

The second reason for this story is to demonstrate that, “we are there to help, again and again, because a good and happy customer keeps coming back,” as Erik Nilsson puts it. For example, “Following this project, Ortviken keeps calling us with new questions about other things.” Anders Mattsson concludes, “the customer has to trust the supplier and the supplier has to trust the customer – you need to have faith on both sides. It’s the only way this can work.”

Mutual trust and teamwork were essential to overcoming challenges in the disc filter project.