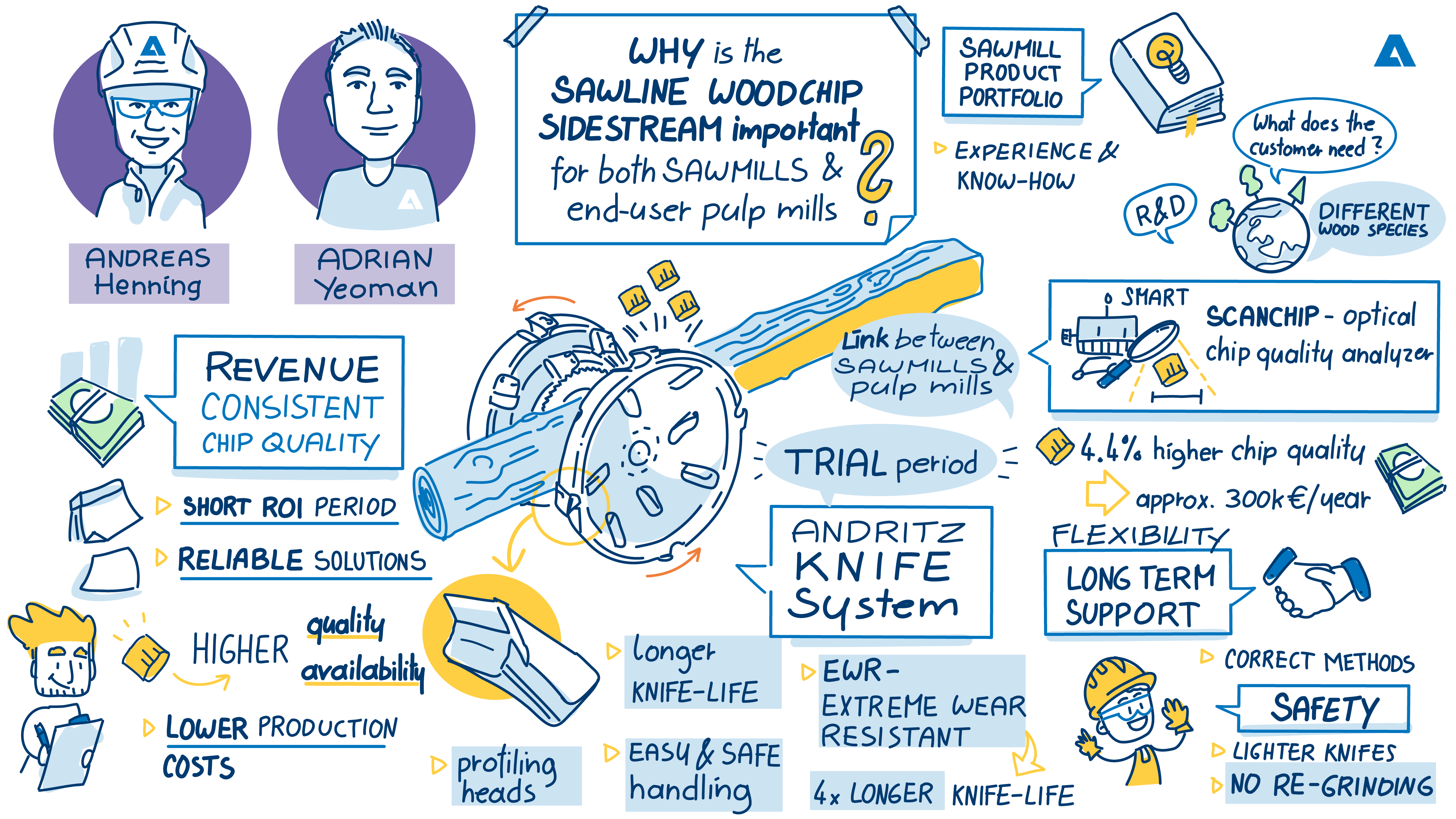

Optimization, data analysis, augmented reality

Wood chip side streams from sawmills: A huge revenue opportunity

With pulp mills facing rising demand for high-quality wood chips along with constrained log supply in some regions, sawmills are well positioned to capitalize on wood chip byproducts as a valuable revenue stream. ANDRITZ has all the dedicated solutions for sawmill operators to optimize production, ensuring consistent delivery of premium wood chips to meet pulp industry needs.

“Sawmills are often focused on their main revenue stream; sawn timber products,” says Andreas Henning, Global Product Group Manager, ANDRITZ. “However, good quality wood chips from sawline side streams can offer a remarkable added revenue stream. The emphasis here is on high quality, as pulp mills will pay extra to ensure a more productive and efficient operation.

"In addition to offering sawmills a valuable supplementary revenue stream, the wood chip market provides greater consistency in demand when it compared to the sawn timber market. This stability enables sawmills to achieve more predictable financial returns, thus supporting long-term planning and reducing exposure to fluctuations commonly experienced in traditional lumber markets."

Adrian Yeoman, ANDRITZ Customer Service Manager, for Australia and New Zealand, adds, “Furthermore, sawmill wood chips tend to be of a better quality and higher density as they usually come from the outside of the log, which makes them ideal for the pulping process.”

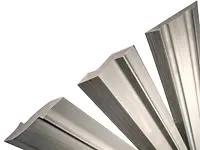

ANDRITZ PowerHead canter with TurnKnife system

A HOLISTIC APPROACH TO PRODUCING HIGH QUALITY CHIPS

To take advantage of the added revenue stream, sawmills need to ensure chips are of the highest quality – and this is where ANDRITZ comes in. The company’s mission in the supply of chipping technology is to always work to improve chip quality, reduce operational costs, increase uptime, and maintain consistent output.

“ANDRITZ takes a holistic approach to the supply chain in handling the sawmill side streams,” explains Henning. “We achieve the best results when it comes to chip quality by the design of our canter heads and knife systems which are produced at our dedicated facility in Sweden.

“Our experience and know-how are completely focused on producing equipment with safe operation and maximized availability, which includes selecting different materials for wear characteristics according to the various wood species used in regions of the world.”

ANDRITZ sawmill products are designed and manufactured specifically for the species of wood being processed at individual sawmills. Specialist technology includes debarking and chipping equipment, including its PowerHead canter and the well-known TurnKnife system. This equipment is in use at sawmills around the world – operating on various wood species in a variety of climates.

“ANDRITZ has a dedicated R&D group working on optimizing chipping quality with different wood species,” says Yeoman. “There can be vast differences in knife wear between one species and another; therefore we carry out intense trials on our customers’ raw material, as well as offer support at the sawmill sites with ongoing optimization.

“In the trials we have carried out, our standard knives can double the lifetime over conventional knives used at sawmills, and our extreme wear resistant knives (EWR) can quadruple the lifetime. In a trial we carried out at the Napier Pine mill in New Zealand we increased the lifetime of the knife from 20 to 80 hours by using EWR knives, which represents an excellent return on the customer’s investment.”

High quality chips on a sawmill by ANDRITZ equipment

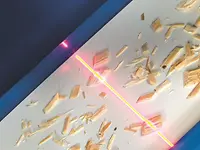

A DIGITAL FUTURE AT SAWMILLS

Sawmill technology from ANDRITZ has not escaped the digital transformation. Technology available for chipping includes the SMART ScanChip Optical chip analyzer, which uses image analysis technology to monitor chip quality in a fast and accurate way. The ScanChip system is designed for either online version integration with the sawmill’s control system or offline as a laboratory instrument.

Henning concludes, “Our chipping technology, whether the hardware of our knife systems or our digital solutions, revolves around producing the highest quality chips in the most efficient way and with the utmost safety. Working closely with our customers, ANDRITZ technology and know-how can make a huge difference when it comes to sawmills in terms of quality of chips, higher wood yield, safety, availability, and sustainability.”

ANDRITZ Smart ScanChip optical wood chip analyzer

SAFETY ASPECT

Safety is paramount when it comes to using ANDRITZ chipping technology, with the emphasis on minimizing handling. Henning says, “Safety is extremely important when it comes to knife handling, both for our customers and our own personnel. We have designed our knives to be much lighter than conventional alternatives, and they weigh grams as opposed to kilos. We also reduce the handling by using the knives until they have worn to the maximum, thus eliminating the need for regrinding.”