Meet ANDRITZ Nonwoven & Textile all over the world

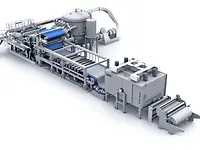

Drying processes for wetlaid production lines

Spot-on drying to suit your process needs

Swift and efficient drying cost-effectively with the ANDRITZ through-air dryer, can dryer and oven.

Through-air dryer

The through-air drying process ensures bulky, porous, and soft product properties. Independent wet and dry temperature zones can be individually adjusted to optimize the drying curve.

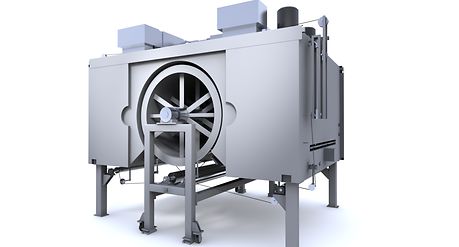

Can dryer

The can dryer is assures homogenous moisture reduction via contact drying. The dryer capacity is aligned to process speeds.

Oven

Specially equipped to suit even glass and carbon fibers. The uniform drying properties provide ideal drying conditions, while maintaining the necessary moisture levels.

Through-air dryer

The ANDRITZ Asselin-Thibeau technical center in Elbeuf, France, comprises a pilot needlepunch line in industrial scale.

The ANDRITZ Küsters technical center in Krefeld, Germany, has a wetlaid/wetlace pilot line, production and pilot textile and nonwoven calenders, as well as various finishing machines.

The ANDRITZ Perfojet technical center in Montbonnot, France, is fully equipped with spunlace and spunjet pilot lines.

The ANDRITZ Diatec technical center in Collecorvino, Italy, comprises pilot lines for the production of nonwovens converting for hygiene, laminating and food pad production

In addition, ANDRITZ maintains extensive test facilities for airlay and textile recycling at ANDRITZ Laroche in Cours, France.

Benefit from:

- Expert support in basic trials, product development, and pre-production settings

- State-of-the-art equipment

- Fair pricing for various tests customized to your needs

- Integrated laboratory to test nonwoven fabrics

- Full documentation of all test results

- Direct support by all experts from technology, sales and service

- Discreet processing of all test runs for your safety