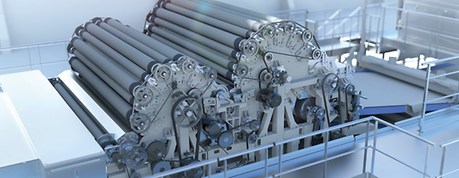

Spunlace line solutions

Build up your future in spunlace with ANDRITZ Nonwoven

For more than three decades, ANDRITZ has led the technical innovations in the spunlace markets, which are continuing to grow. Spunlace is the processing of staple fibers with bonding by water injection, called hydroentanglement. Expertise and commitment from the core team at ANDRITZ Perfojet creates customized solutions for an industry that is constantly reinventing itself and its products.

As versatile as the ideas of its producers

Today, end products from spunlace production lines can be found in many areas, both as disposable products and durables: personal care, household and industrial wipes, hygiene articles, face masks, cosmetics, but also in filter products and items for the automotive industry such as battery insulation or noise encapsulation.

All components in perfect harmony

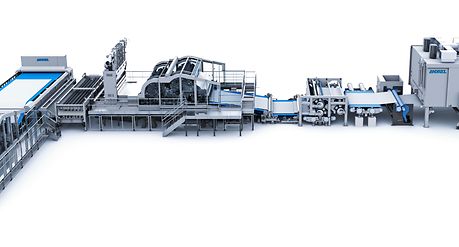

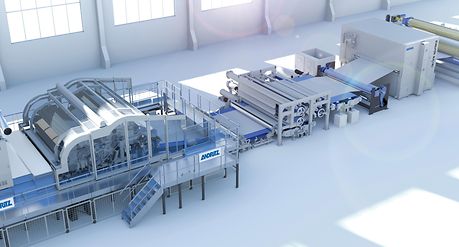

ANDRITZ turnkey systems create a cost-efficient, flexible, and reliable spunlace line from opening/blending to the slitter and winder. The core of our expertise is in arranging and configuring the main process components in the production line so that they work in harmony to deliver the desired end product perfectly.

We will be happy to advise you on all your questions and concerns for your individual equipment and configuration.

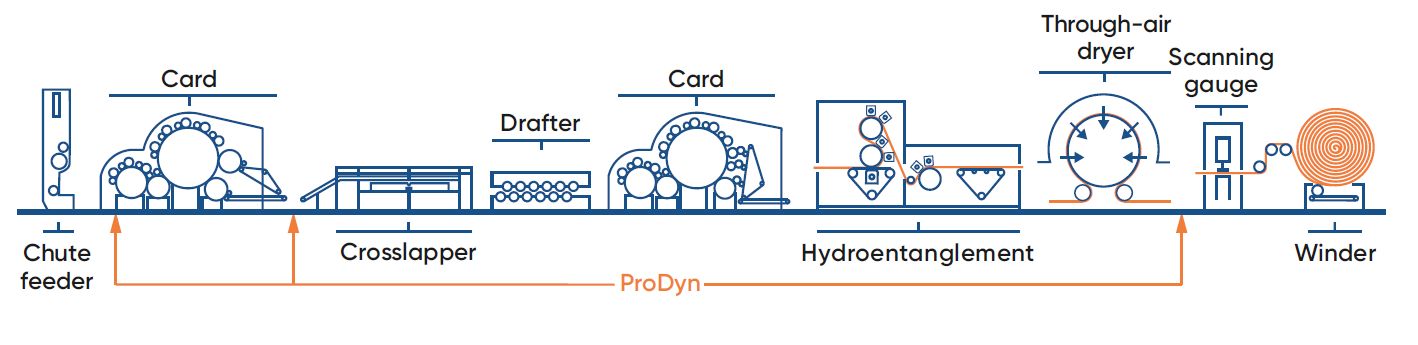

ANDRITZ Spunlace line with crosslapper

© ANDRITZ

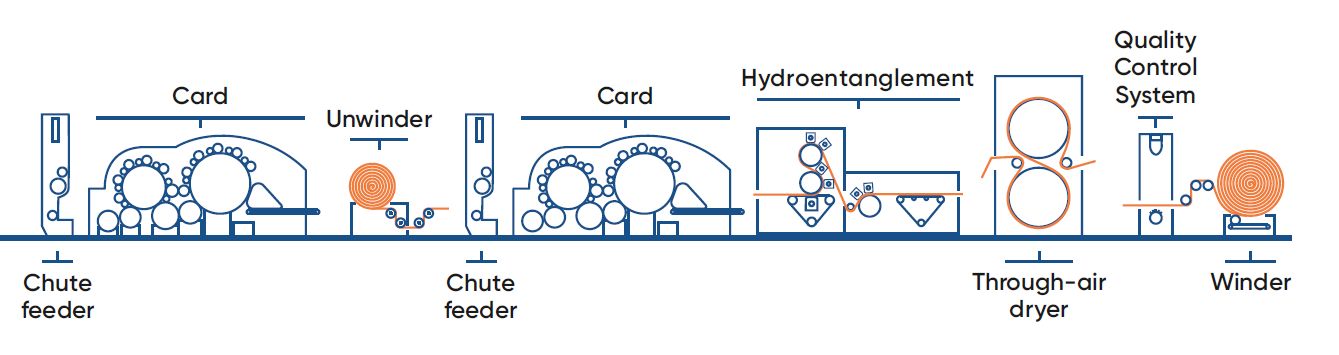

ANDRITZ Spunlace line eXcelle

© ANDRITZ