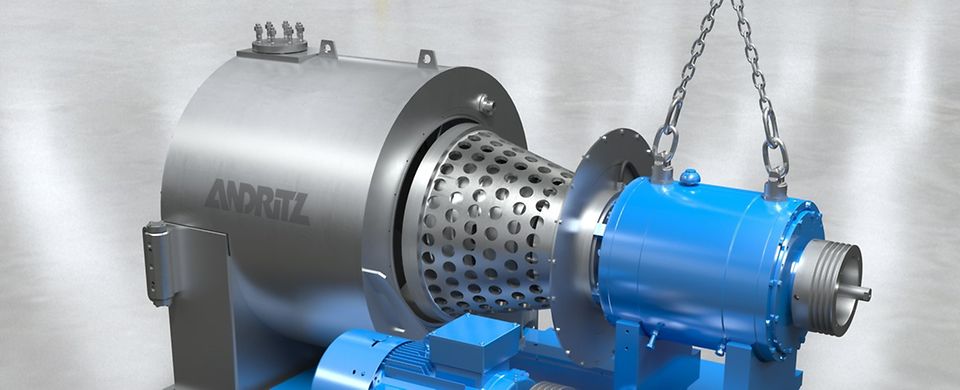

Ideally suitable for bulk chemicals, agrochemicals, food, and much more, this new generation of screen scroll centrifuges is distinguished by its express cartridge to give maximum uptime and easy maintenance, an innovative feeding system to reduce wear and particle attrition, as well as its modular scroll design for efficient and convenient maintenance. In short, the ANDRITZ screen scroll centrifuge HX enables reliable and uninterrupted operation, with minimum downtime and maximum ease of maintenance.

Engineered for reliability – modular centrifuge design with low maintenance requirements

The screen scroll centrifuge HX features a maintenance-friendly design with a modular scroll architecture that simplifies servicing and reduces downtime. This supports long-term reliability and lowers the total cost of ownership, making it ideal for continuous operation in demanding environments.

Express cartridge: No disconnecting of process piping during maintenance work

With this screen scroll centrifuge, the entire rotating assembly (cartridge) can be removed quickly and replaced with a spare cartridge to reduce the overall downtime to less than 8 hours. While the machine is operating with the spare cartridge, the original cartridge can undergo maintenance in a service center so that production downtime is limited to a minimum even if major maintenance work is required.

GentleFeederTM system – reduced wear, improved product quality

The GentleFeederTM system ensures smooth acceleration of solids, minimizing particle breakage and wear. This enhances separation performance, extends component life, and improves the quality of the final product - especially important in sensitive applications like food processing and chemical production.

Technical highlights, process capabilities, and applications

The HX centrifuge handles feed materials with particle sizes >100 µm and solids concentrations >10%. It achieves solids recovery rates up to 98% and supports throughput of up to 60 t/h. The screen centrifuge design minimizes plugging and maximizes active filtration area, while the scroll centrifuge mechanism ensures efficient solids transport and discharge.