ANDRITZ filter cloths and plates for filter presses

The ideal filter cloth for every need to ensure efficient and reliable separation

When choosing the ideal filter cloth, ANDRITZ uses its extensive knowledge in the filtration segment and takes account of various factors, such as the product to be filtered, pH, temperature, feed pressure, concentration of solids, desired residual moisture, and filtration time.

Possible features

- Fibers: polypropylene (PP), polyester (PES), polyamide (PA)

- Threads: Monofilament, multifilament, cut fiber and mixed

- Filter cloth finishing: Smooth, waterproofed or with reinforced seals

- Execution: Single, double, overlapped, and hermetic filter cloths

- Air permeability of the materials: From 1 to 1500 l/min/dm2 at 200 Pa

- Thermofixed fabrics: Guarantee better dimensional stability, avoid problems with shrinkage

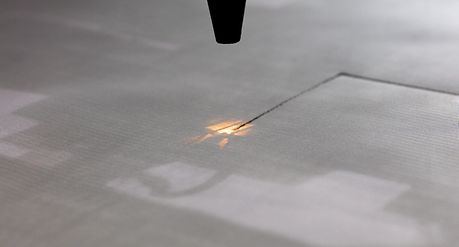

- Supercalendered fabrics: Adjust the permeability of the material, ensuring a smoother surface and easier removal of the cake at the end of the process

- Backing cloth: In specific applications, it is used to maintain drainability andextend the lifetime of the filter cloth

- Fixing systems: Filter cloths with metallic grommets or synthetic grommets (attached by ultrasound or velcro)

- Barrel neck material: Waterproofed or made of rubber.

- SmartFEED: A new feed shoe that reduces the downtime of a filter press enormously. The combination of two single filter cloths with the new feed shoe revolutionizes the process of cloth changing

- Different plate designs: center, angular and bottom inlet

- Tests: On-site tests to determine the ideal filter medium for your process at no extra cost

Your benefits

- Up to 20% longer filter cloth lifetime and higher cake solids content

- Reliable separation of even the smallest particle sizes

- Wear resistance

- Easy filter cake discharge

- High stability, even on surfaces with larger filter elements

- Standard or customized design to meet your specific requirements

ANDRITZ Separation filter cloths are currently installed in over 10,000 press filters of all models and makes worldwide. With 150 years of experience in the solid/liquid separation process, ANDRITZ can provide the ideal filter cloth for all applications and specific needs.

As a supplier of complete solutions in solid/liquid separation equipment, ANDRITZ Separation recognized the demand for quality filter cloths and began manufacturing these components in 1995. Since then, ANDRITZ Separation has worked continuously on development and optimization of filter cloths. If needed, ANDRITZ can even offer customized solutions with a variety of finishes and sizes (from 250 mm up to 3000 mm) and reduced production times in order to meet all of your needs.