Extraordinary results

- Energy savings of >5 kWh/t

- Production increase of 25%

- ROI ~2 years

- Increase in outlet consistency

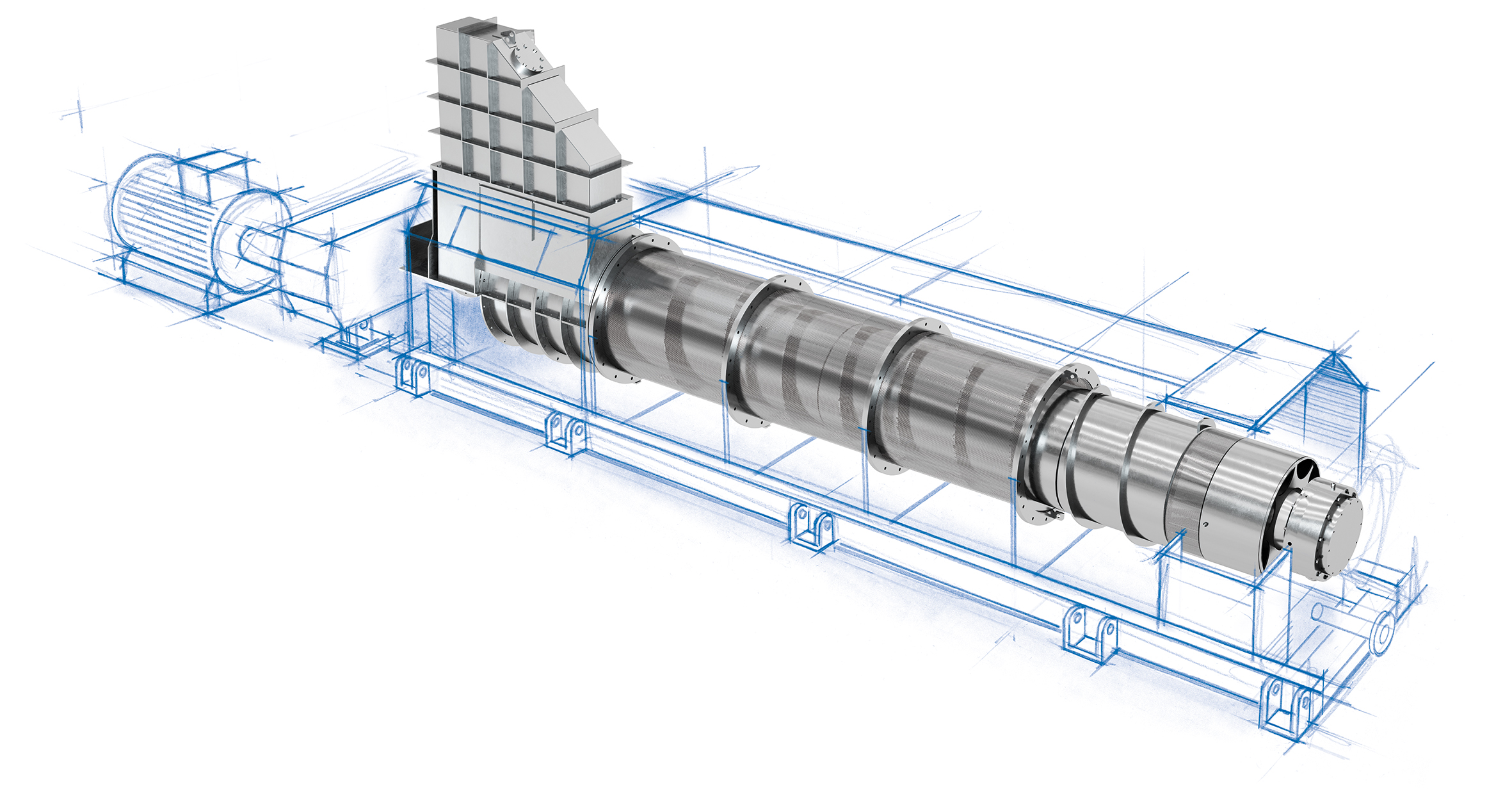

When the time came to replace a worn screw press shaft, the target was mainly to maintain output volume and quality. But the new Low-Energy Screw Shaft (LESS) did better, slashing energy consumption as well.

The ANDRITZ screw press was installed in the DIP line of a European paper mill that supplies pulp for white top liner and LWC. The project target was straightforward: The upgraded screw press should deliver at least the same quality and throughput as before. However, ANDRITZ had some new ideas …

The results exceeded our customer's expectations. The LESS design can be used on all types of screw presses. Such optimizations show that smaller changes to single machines or subsidiary systems also have an influence on the ecological footprint of the entire mill.

You would also like to improve the energy efficiency of your screw press or learn about its optimization potential? Based on your specific requirements, our service experts can find the right solution to your problem.