Optimization, data analysis, augmented reality

Twin wire press roll services

Highest availability and performance of production equipment is a must for today’s pulp and paper makers. In twin wire presses, the press and drive rolls play an essential part in ensuring excellent sheet quality and outlet dryness, even at the highest specific production rates.

ANDRITZ, a distinguished expert in roll supply, is renowned for its unwavering dedication to quality. Drawing upon decades of experience in manufacturing rolls numerous twin wire presses, sludge dewatering machines, paper/board machines, and high-speed tissue machines worldwide, ANDRITZ has unparalleled expertise in roll services.

ANDRITZ is a supplier of high-quality rolls

ANDRITZ specializes in the repair, refurbishment, and enhancement of all types of rolls utilized in twin wire presses, regardless of their make or manufacturer. This is conducted within workshop facilities strategically located in key regions to serve our customers effectively. They are equipped with state-of-the-art machinery and tools as well as skilled professionals.

All steps within a single line

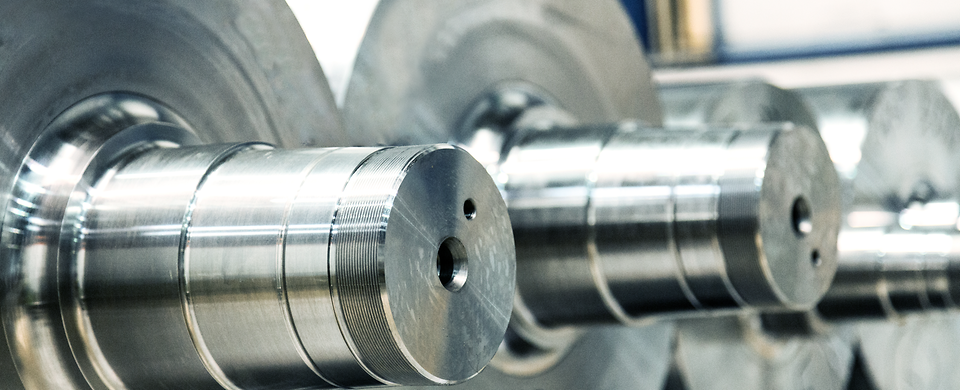

In 2023, ANDRITZ opened a cutting-edge roll production line at its plant in Graz, Austria, enabling the seamless execution of all process stages to significantly reduce turnaround times. This streamlined approach involves technicians experienced in every aspect of roll processing, facilitating parts delivery, roll tube machining, welding and mounting of the roll cladding, and roll shaft insertion, all within a single line.

New roll manufacturing, repair, and upgrade line in the ANDRITZ facility in Graz, Austria.

We offer a variety of solutions

- Roll repairs, including failure analysis

- Roll covering replacement from 0 to 30 P&J

- Replacement of rubber or polyurethane (PU) covers with durable, stainless steel-clad roll covers, smooth or grooved

- Upgrade solutions for existing rolls

- for longer lifetime

- to increase pulp quality or machine performance

Our know-how from thousands of twin wire press rolls produced is your benefit.

Grooved stainless steel-clad rolls are recommended when a high dewatering capacity is required.