|

|

|

One partner for all roll related services.

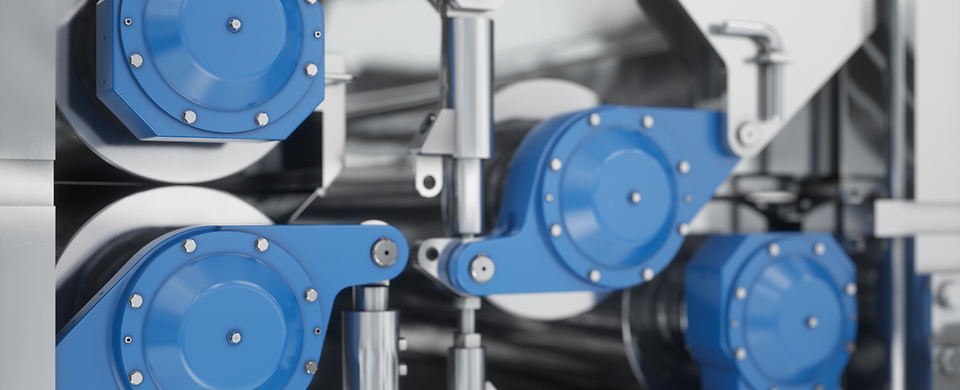

With more than 600 twin wire press installations around the world and over 70 years of experience, ANDRITZ is your reliable partner for twin wire press technologies, spare and wear parts, as well as customer-specific services.

Twin wire presses are installed in numerous dewatering processes in the pulping industry, such as sheet drying and wet lap systems, HC bleaching systems, dewatering, and washing. Benefit from our manufacturing know-how and let us help you integrate the right products in your individual processes – be it state-of-the-art spare, ware, and replacement parts or engineered service solutions for your press. We have proven time and again that our service products in combination with our process expertise lead to a measurable increase in production efficiency and a lower total cost of ownership.

We offer a wide variety of upgrade products that not only improve performance but also provide energy and cost savings as well as ROI within a very short space of time.

|

|

|