Benefits of ANDRITZ LignaRec lignin recovery

- Environmental and economic savings

- Debottlenecking of recovery boiler

- Substitute biofuel for lime kiln

- Additional revenue stream as bioproduct raw material

One of ANDRITZ's latest innovations, LignaRec lignin recovery, shines a new light on the chemical cycle in a kraft mill. It offers tailored solutions to optimize the chemical balances in the mill and provides the ability to generate additional revenue and/or avoid the purchase of costly make-up chemicals.

Lignin is a main wood component that is separated during the cooking process and combusted in the chemical recovery boiler as an organic compound in concentrated black liquor.

For kraft mills, lignin recovery presents an opportunity to generate new revenue streams by replacing fossil materials with lignin. This process is particularly advantageous when there is a need to remove and recover lignin from the recovery boiler to alleviate bottlenecks. Lignin has immense potential for various end-use applications, including its use in composites and as a substitute for phenol and aromatic compounds.

There is also the potential to create an additional revenue stream as high-quality lignin is a bioproduct in demand as a raw material for composites or as a substitute for phenolic and aromatic compounds.

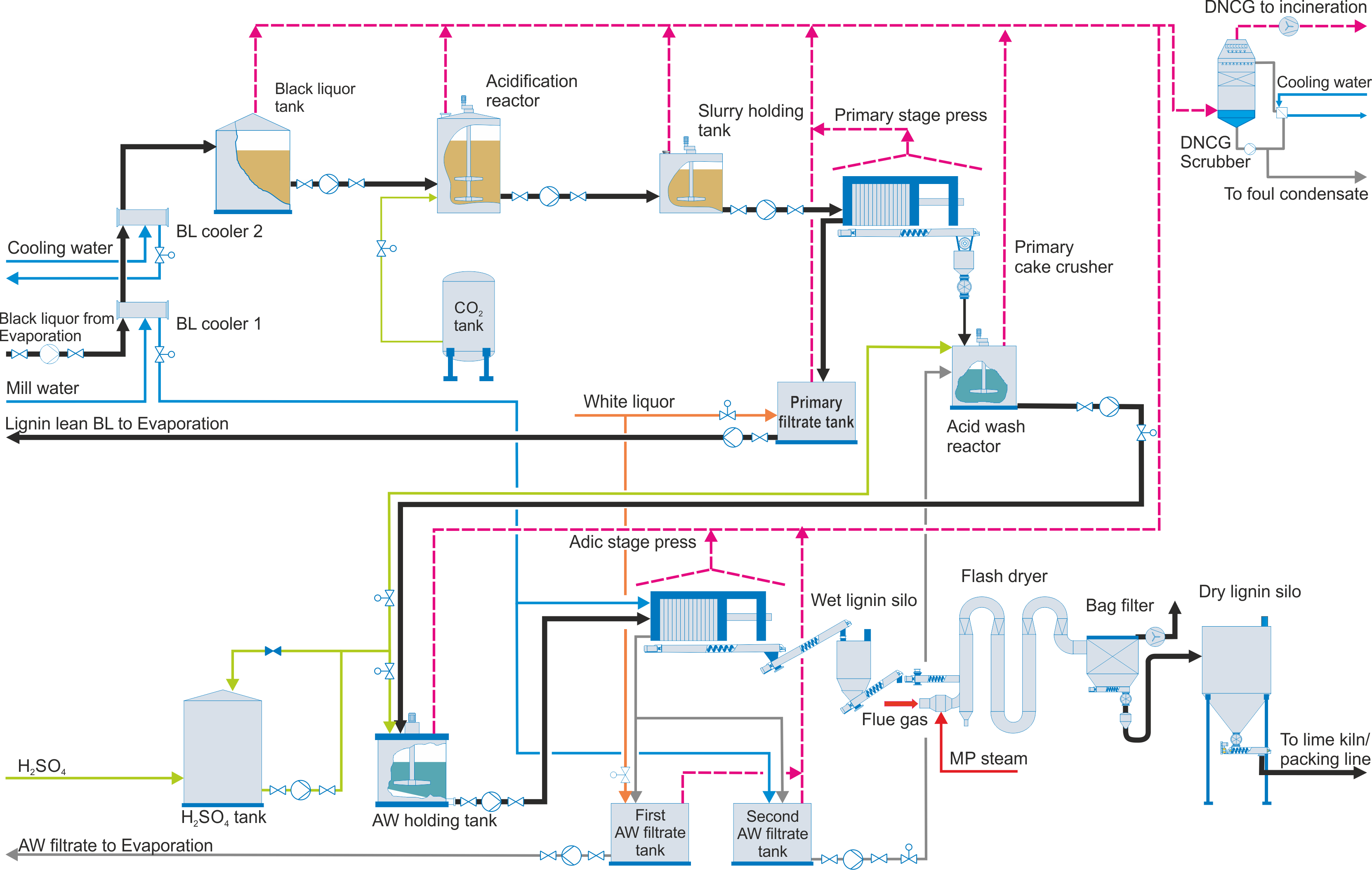

Depending on the intended use of the lignin, ANDRITZ tailors the lignin recovery system to achieve a mill’s exact goals. The LignaRec lignin recovery process is designed to remove lignin from black liquor at 35–45% dry solids, having a typical pH of 12–13. After filtration and washing, the dry solids lignin content is typically 60–62% before the drying stage and 95% afterwards.

Recovered lignin cake

In its most complete form, LignaRec lignin recovery consists of these sub-processes:

As with many ANDRITZ solutions, the company can deliver a complete plant – with the process design; main equipment including lignin recovery process with ANDRITZ filter presses, dryer, and lime kiln burner, as well as automation, and erection – from one source.

The ANDRITZ LignaRec lignin recovery process

LignaRec™ lignin recovery is part of the ANDRITZ’s CircleToZero initiative, which includes new technologies aimed at optimizing pulp mill side streams. This global initiative for our pulp and paper customers brings together the continuous development and improvement of existing ANDRITZ technology solutions with an ambitious innovation goal for the future: To eliminate unused side streams, create new added-value products, and lay the foundation for zero emissions and zero waste production.