Sugar

Wear-resistant and non-clogging pumps are a prerequisite for trouble-free operation in the sugar industry. ANDRITZ single-stage centrifugal pumps set new standards and achieve efficiencies of up to 90%. These pumps have either closed, semi-open or open impellers depending upon where they are installed in the sugar production process. According to the flow rate required, they are used from beet washing to juice purification and to crystallization.

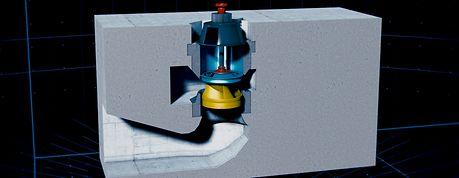

In ANDRITZ self-priming centrifugal pumps, an open impeller with an integrated water ring vacuum pump is used to achieve high priming and degassing performance. This guarantees smooth operation, even with suboptimal suction pipe configurations. The vacuum pump removes gas from the medium to guarantee trouble-free transport of the syrup. The unit is insensitive to high concentrations up to a sugar content of 78% due to the semi-open impeller. It also provides better efficiencies with viscous media compared to closed impellers. Thanks to these design features, ANDRITZ self-priming centrifugal pumps are perfectly suited for the sugar industry, conveying syrup with high air and sugar content at low investment costs.

ANDRITZ also offers a practically tested medium-consistency pump to transport molasses, green juice, white juice, lime water, or sludge.

For more information on our pump technologies for the sugar production from either sugar beet or sugar cane please have a look at our product pages below and brochures in the sidebar or directly contact us.